When brewing beer, yeast is produced as a by-product. This product is usually treated as waste. Brewer’s yeast, however, contains valuable ingredients, such as amino acids, proteins, and minerals. These ingredients can be re-used in several food products. This dip feed single drum dryer (or roller dryer) is specially designed for this purpose.

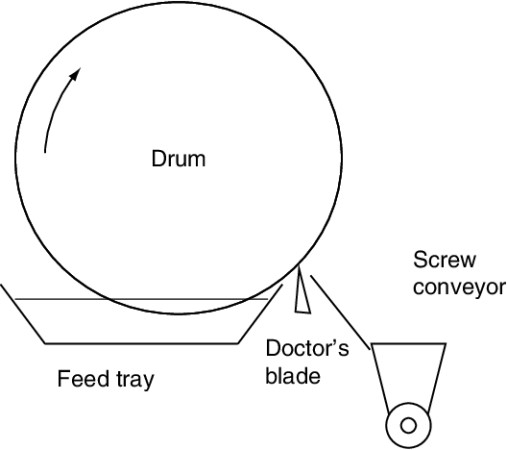

This dip-feed single drum dryer (or roller dryer) is a continuous indirect-heating drying processor. The dryer body consists of rotary drum heated by steam, dip feed tray, scrapper and exhaust hood. Liquid raw material is pumped into the feed tray installed just below the rotary drum, where the bottom of rotary drum dips into the liquid material. Liquid material sticks to the hot drum surface and form a uniform thin layer with the help of applicator roller. Moisture evaporates very quickly. Drying process is done within a single rotation of the drum and the dried product is scrapped off with the knife.

HG series rotary drum dryer (or roller dryer) with its continuous indirect drying method, allows short heat retention time while evaporating all the liquid within a single rotation of the drum. It not only virtually eliminates the risk of damaging the product but also enables the product to keep its unique properties like taste, smell, texture etc. Drum dryer is unique for drying viscous, pasty and sticky materials in food, chemical and pharmaceutical industries.

Dip-feed drum dryer has the following overwhelming advantages in drying brewer’s yeast:

1) High heat efficiency: Heat loss is mainly caused by thermal radiation. Heat efficiency can be as high as 90%.

2) Short drying time: The drying process only takes 10-15 seconds. So drum dryer can be used for drying heat sensitive material.

3) Uniform drying: Heat transfer direction and coefficient all over the drum surface are the same. And wet material can be evenly spread over the drum surface. Wet material can be uniformly dried.

4) Long life span: The drum is made by high-quality cast iron and coated with hard chrome plate to get perfect smoothness and hardness.

5) Flexible application: Drum surface temperature, rotating speed, wet material film thickness are all adjustable to satisfy materials with different moisture and drying time.

6) Compact size: The drying chamber is very compact in size. Only need small installation space.

7) Low operation cost: The whole machine is very simple and reliable. It can be used for many years with little repair and maintenance.

8) Highest hygienic standard: Indirect heating and the drum is completely covered can assure highest hygienic working condition and safety.

GB-1800x2500 Dip-feed Drum Dryer

GB-1800x2500 Dip-feed Drum Dryer in Spain

Hot News

Hot News

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy