WFJ Air Classifier Mill (ACM) is vertical impact mill with a built-in air classifying wheel to control product particle size distribution. ACM is most commonly used for fine and ultra-fine grinding of soft to medium hard materials.

WFJ Air Classifier Mill (ACM) is vertical impact mill with a built-in air classifying wheel to control product particle size distribution. ACM is most commonly used for fine and ultra-fine grinding of soft to medium hard materials.

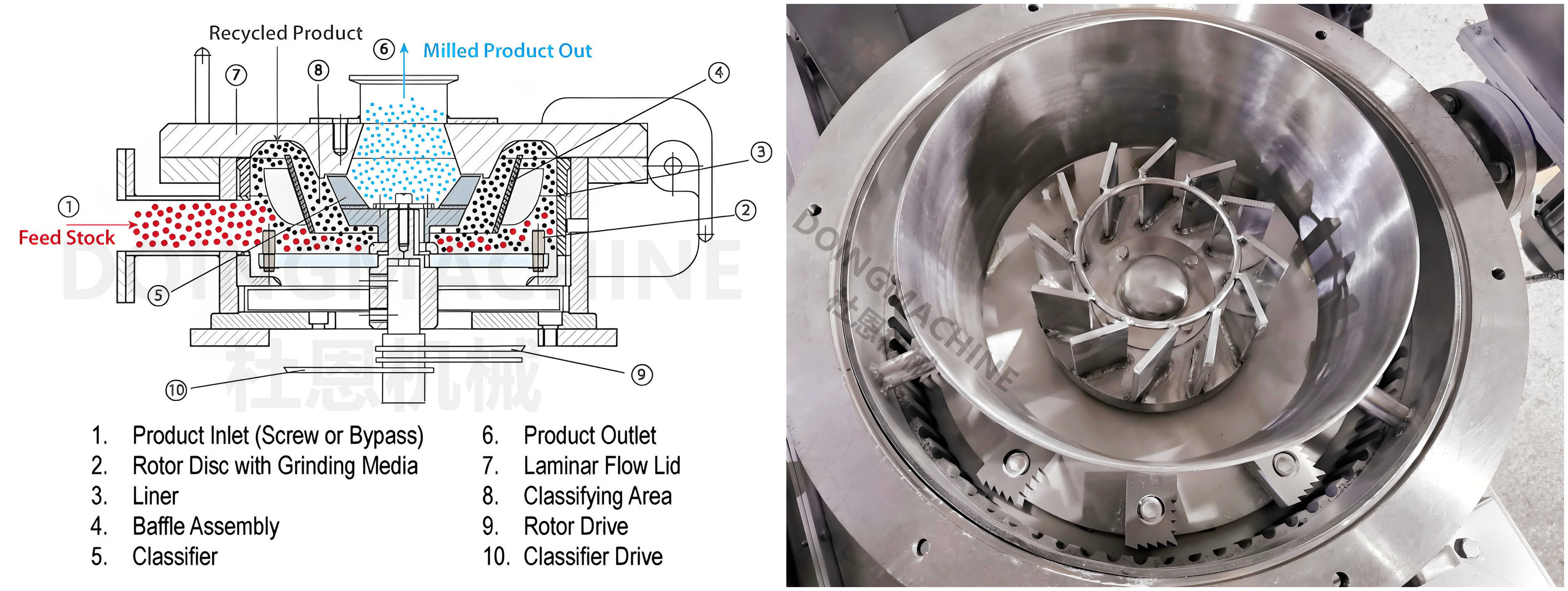

Material is fed into the grinding chamber via screw feeder and strongly impacted and collided into fine powder between the high-speed disc rotor and teeth liner. The product is then carried to the classifying section by airflow where qualified powders pass through the classifying wheel and discharged as products; coarse powders are rejected by the classifying wheel and returned to the grinding zone for further comminution. Final product is collected by cyclone and bag house.

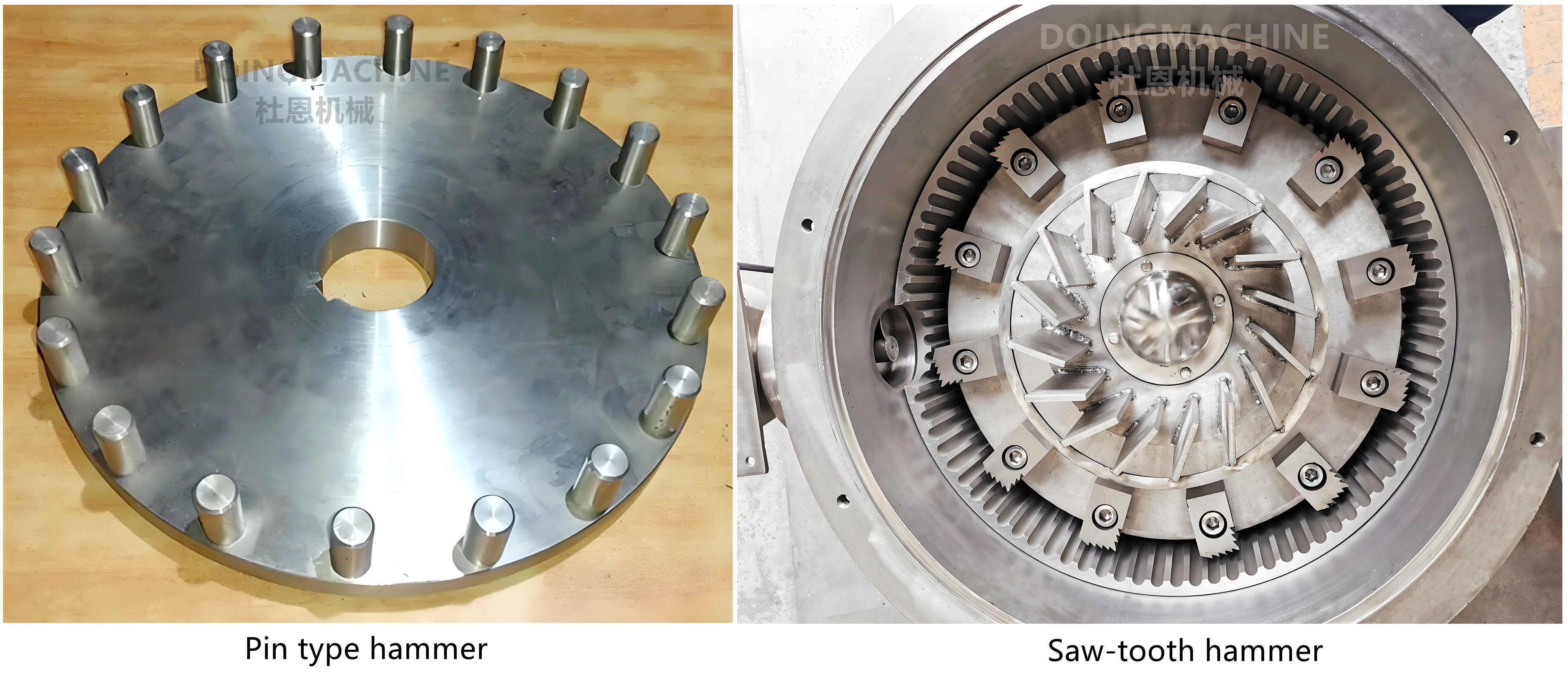

1. Grinding hammer options. Different type and quantity of hammers can be installed on the impact disc rotor according to specific raw material and size distribution requirement. Hammers are bolted to the rotor disc and can be easily removed and replaced. Options include:

2. Accurate product size control. Air classifier mill integrates impact mill and air classifier into a single unit. There is no need to use sizing sieve and the product particle size can be accurately controlled by adjusting the rotation speed of air classiying wheel.

3. Product temperature control. The strong airflow can cool the product quickly to ambient temperature. Cooled air can be introduced into the grinding chamber for heat sensitive raw material.

4. Speed control: The screw feedrate, disc rotor speed, air classifier speed and airflow rate can be separately controlled by VFD to optimize the milling process.

5. Sanitary design: Made by SUS304 or SUS316 stainless steel and well polished to meet food-grade or GMP sanitary requirements. The grinding chamber can be easily dismantled for cleaning or replacing grinding elements.

Technical Parameters:

| Model | WFJ-10 | WFJ-20 | WFJ-30 | WFJ-60 |

| Capacity (kg/h) | 10-100 | 30-300 | 50-600 | 100-1000 |

| Feed size (mm) | ≤10 | |||

| Product size (mesh) | 80-350 Mesh (180-45 microns) | |||

| Grinding motor (KW) | 5.5 | 15 | 30 | 45 |

| Rotation speed (RPM) | 6000 | 5400 | 3800 | 3200 |

| Air classifier motor (KW) | 0.75 | 1.5 | 4 | 4 |

| Draft fan (KW) | 4 | 7.5 | 15 | 30 |

| Dimension (mm) | 4200x1250x2700 | 4700x1250x2900 | 7800x1800x3900 | 8100x2300x4600 |

| Gross weight (KG) | 800 | 1250 | 2300 | 3500 |

Note: The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Air Classifier Mill is customized. The following information is needed to work out a detailed quote:

1) Raw material name, size and hardness. Samples might be needed for tests.

2) Required product particle size;

3) Required grinding capacity in kg/h;

3) Power supply type: 220V/380V/415V/440V, 50/60Hz, three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy