This Lab Fluid Bed Dryer is used to dry free-flowing wet powders and granular materials in lab for formulation development.

This Lab Fluid Bed Dryer is used to dry free-flowing wet powders and granular materials in lab for formulation development, such as wet powders (or mix) from high shear mixer; granules from basket granulator or screw extruder etc.

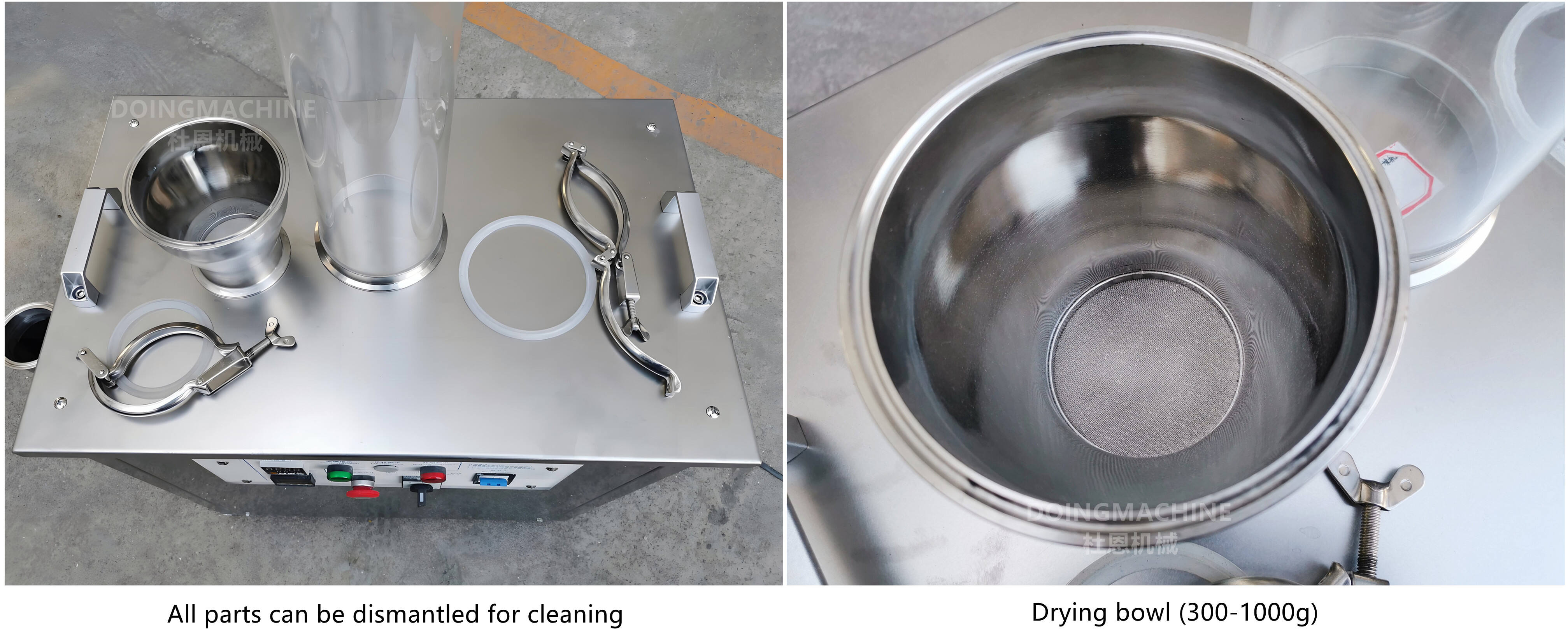

Wet material is manually fed into the drying bowl of which the bottom is made by stainless steel sintered mesh. The fan blows hot air though the drying bowl to fluidize the wet material for fast and uniform drying. Both the drying temperature and hot air flowrate can be accurately controlled.

Technical Parameters:

| Model | FBD-1 |

| Drying bowl volume | 1 L |

| load capacity | 100-1000 g |

| Drying temperature | Ambient to 120 ℃ (PID control accuracy: ±1℃) |

| Blower fan | 0.37 KW (with VFD inverter) |

| Electric heater | 1.5KW |

| Construction material | SUS304 or SUS316L |

| Dimension | 500x400x700mm |

| Gross weight | 35 KG |

| Power supply | 220V/380V/415V/440V, 50/60Hz, single/three phase. |

FAQ:

Q: What information is needed in order to get a quote?

A: Our Lab fluid bed dryer is customized according to specific working condtion . The following information is needed to work out a detailed quote:

1) Raw material name, bulk density and particle size etc. Samples might be needed for trial production or drying tests.

2) Load capacity in gram/batch

3) Suggested drying temperature

4) Power supply type. 220V/380V/415V/440V, 50/60Hz, single/three phase.

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 40-50 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy