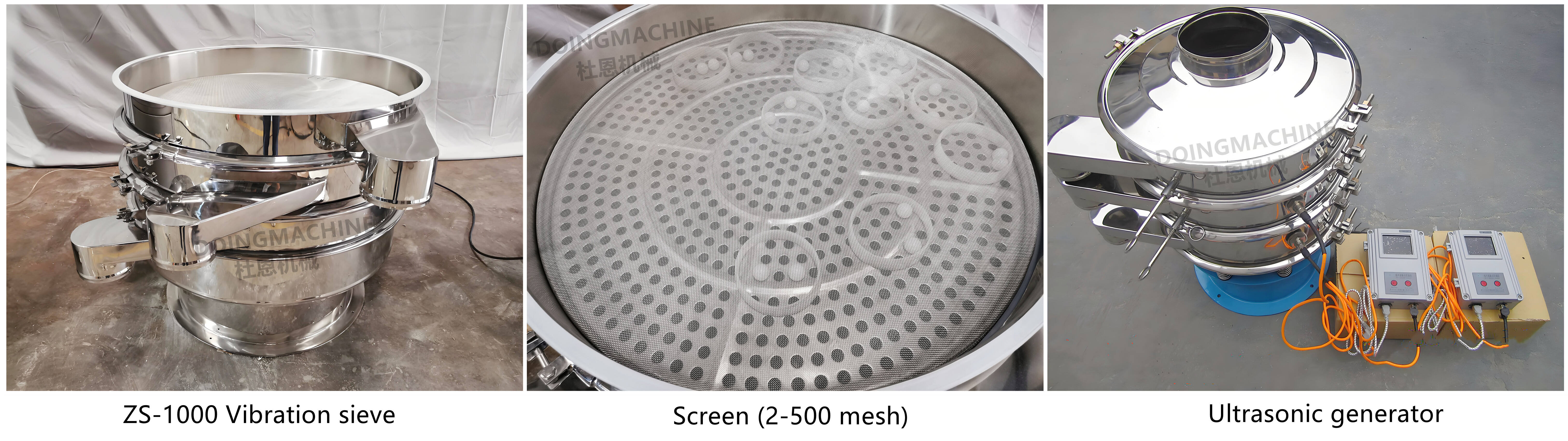

ZS Vibrating Sieve ( also called Vibratory Sieve or Vibrating Screen) is used to screen and classify solid particles or granular materials according to different particle sizes in food, chemical and pharmaceutical industry.

ZS Vibrating Sieve ( also called Vibratory Sieve or Vibrating Screen) is used to screen and classify solid particles or granular materials according to different particle sizes in food, chemical and pharmaceutical industry.

ZS Vibrating Sieve is driven with a vibration motor that produces a horizontal and circular tumbling vibration motion once the centrifugal discs are correctly adjusted, causing the material being screened to move in a spiral pattern starting from the inside and moving outwards. In addition, the vibratory motion can be easily adjusted in order to adjust the screening quality and throughput as required for the application at hand.

Technical Parameters:

| Model | ZS-600 | ZS-800 | ZS-1000 | ZS-1200 | ZS-1500 |

| Screen diameter (mm) | 550 | 750 | 950 | 1150 | 1450 |

| Screening area (M2) | 0.23 | 0.42 | 0.64 | 0.95 | 1.54 |

| Vibration motor (KW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 |

| Screen size | 2-500 mesh | ||||

| Deck quantity | 1-4 layers | ||||

Note: ZS Vibrating Sieve is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Vibrating Sieve can be customized. The following information is needed to work out a detailed quote:

1) What raw materials you are going to sieve. Raw material sample might be needed for trial production or tests;

2) Raw material bulk density and particle size

3) Required screen size and deck quantity

4) Process capacity in kg/h

5) Power supply type. 220V/380V/415V/440V, 50/60Hz, three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy