CT-C Tray Dryer (also called chamber dryer or drying oven) is the most commonly used convective chamber dryer, capable of drying or heating various kinds of wet materials from liquids to bulk solids.

CT-C Tray Dryer (also called chamber dryer or drying oven) is the most commonly used convective chamber dryer, capable of drying or heating various kinds of wet materials from liquids to bulk solids. Inside the drying chamber, trays loaded with wet material are placed on top of each other in trolleys.

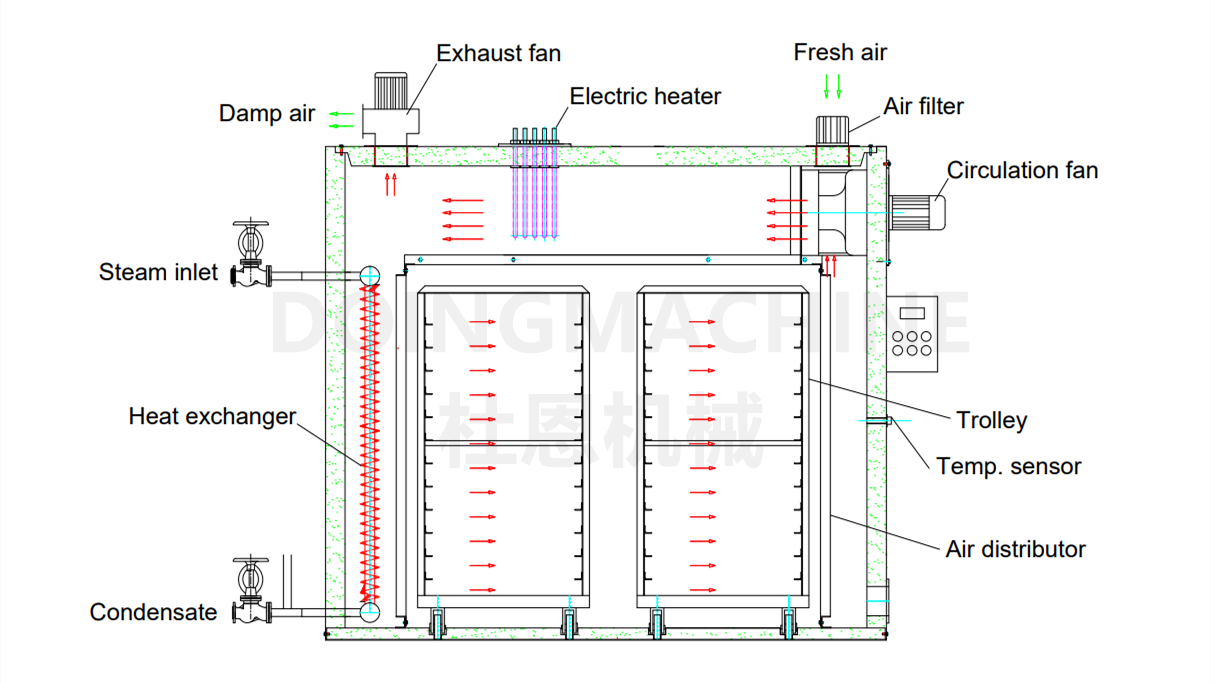

In drying process, fresh air is sucked into the drying chamber by the circulation fan and flows through the built-in electric heater or steam heat exchanger to get required temperature. With the help of air distributor, hot air evenly flows through each layer of trays for heat transfer and carries away the evaporated moisture. Most of the hot air is forced to circulate inside the drying chmaber to save energy, while small amount of damp air is discharged via a draft fan or air valve. After drying, open the chamber door and pull the trolleys out for unloading the dried product.

Technical Parameters:

| Model | CT-C-O | CT-C-I | CT-C-II | CT-C-III | CT-C-IV |

| Load capacity (kg/batch) | 60 | 120 | 240 | 360 | 480 |

| Steam heat exchanger (M2) | 10 | 20 | 40 | 80 | 100 |

| Electric heater (KW) | 9 | 15 | 30 | 45 | 60 |

| Circulation fan (KW) | 0.45 | 0.45 | 0.45 x 2 | 0.45 x 3 | 0.45 x 4 |

| Trolley quanity | 1 | 2 | 4 | 6 | 8 |

| Tray quantity | 24 | 48 | 96 | 144 | 192 |

| Tray dimension (mm) | 640x460x45 | 640x460x45 | 640x460x45 | 640x460x45 | 640x460x45 |

| External dimension (mm) | 1380x1200x2000 | 2260x1200x2000 | 2260x2200x2000 | 3240x2200x2000 | 4280x2200x2000 |

| Gross weight (KG) | 820 | 1580 | 1800 | 2100 | 2800 |

Note: The built-in heat source can be electric heating elements or steam heat exchanger. When use steam, the max drying temperature is about 140 ℃.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Tray dryer is customized according to specific raw material, drying capacity, heat source etc . The following information is needed to work out a detailed quote:

1) Raw material name, bulk density and particle size etc. Samples might be needed for trial production or drying tests.

2) Moisture content before drying; target moisture content in dried product.

3) Load capacity in kg/batch

4) Heat source: Steam, electricity or gas/oil fired hot air generator.

5) Suggested drying temperature

6) Power supply type: 220V/380V/415V/440V, 50/60Hz, three phase.

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 40-50 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy