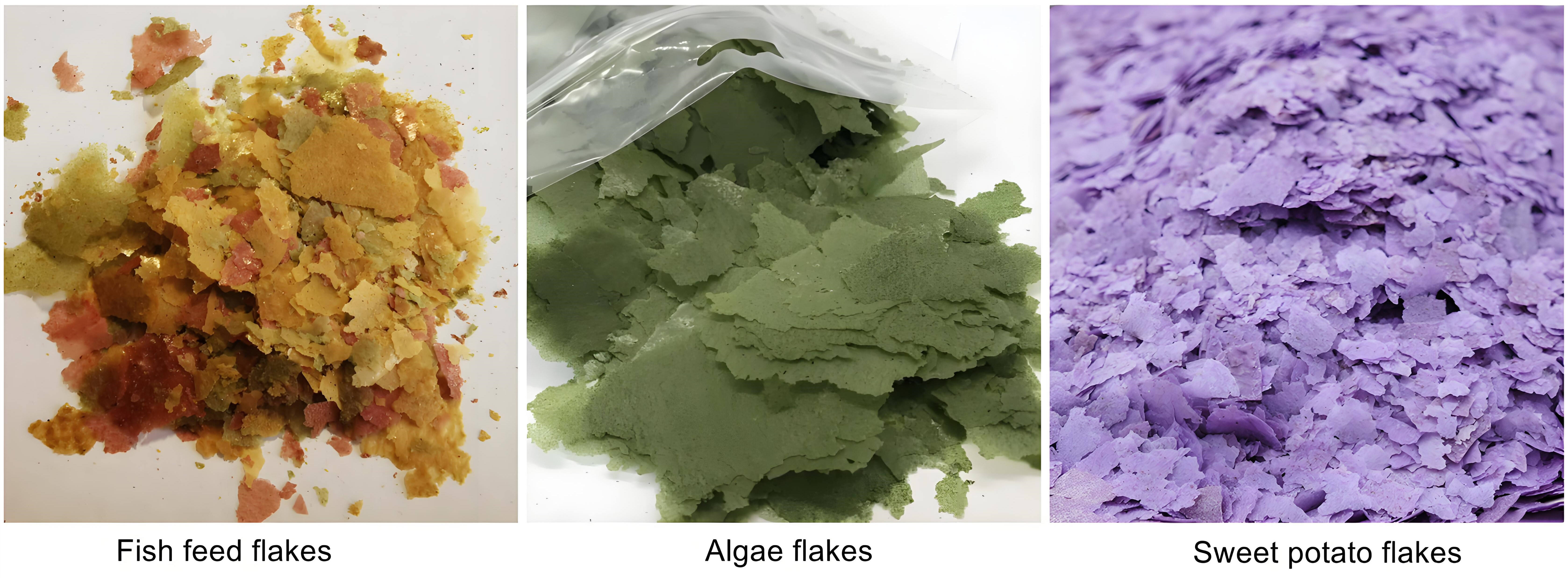

GB To- feed Scraper Roller Dryer (also called Drum Dryer) is continuous indirect-heated drying processor, which is commonly used for drying viscous liquids, slurries, heavy pastes, puree materials in food and chemical industry.

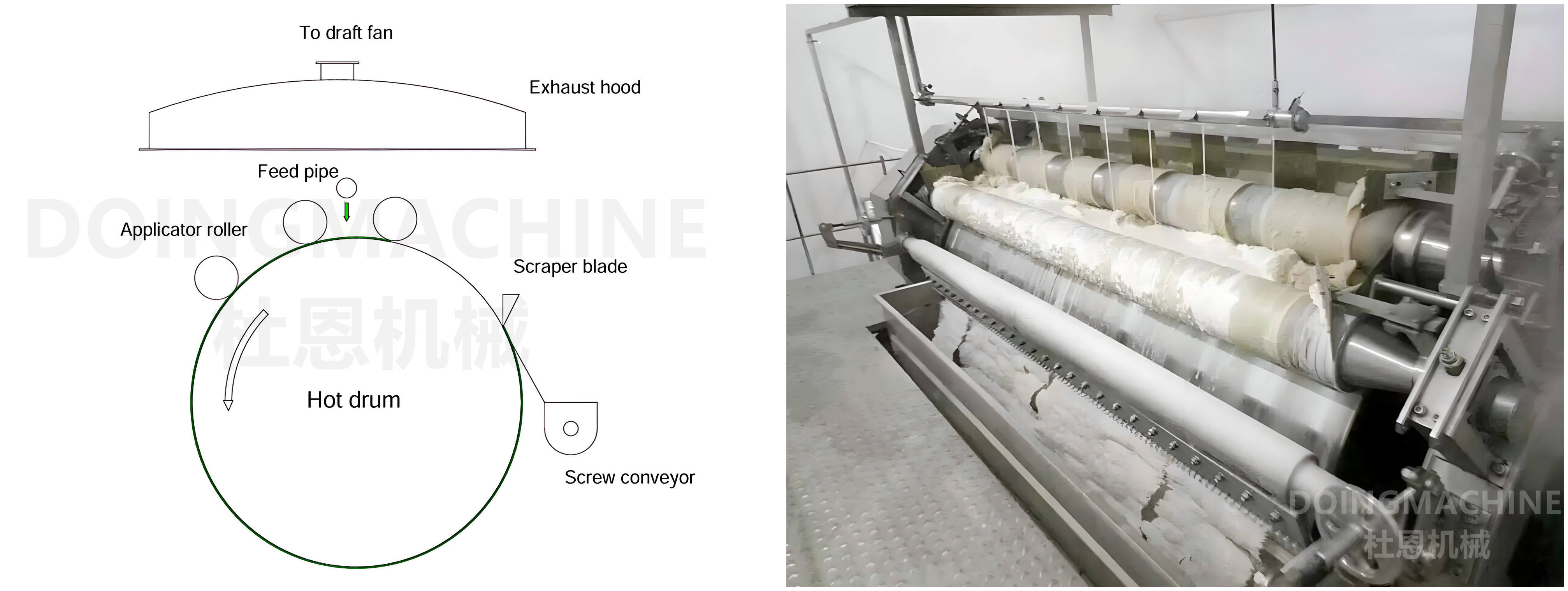

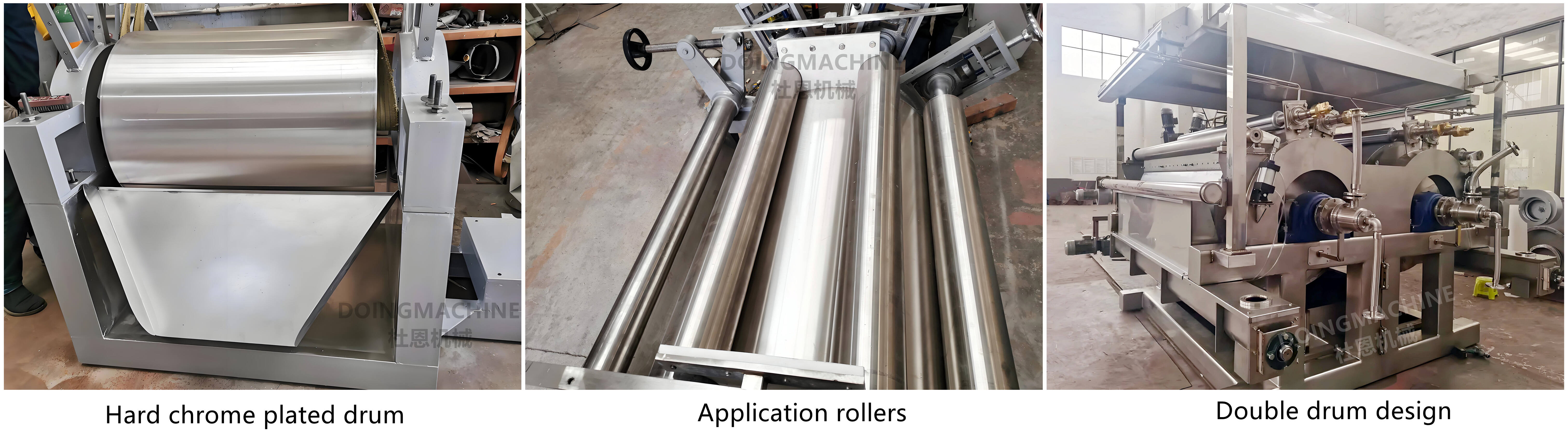

GB Top-feed Scraper Roller Dryer (also called Drum Dryer) is continuous indirect-heated drying processor, which is commonly used for drying viscous liquids, slurries, heavy pastes, puree materials in food and chemical industry. Top feed drum dryer consists of hot drum, drum drive system, applicator rollers, scraper blade, exhaust hood and screw conveyor.

Raw material is pumped into the top feed pipe, which feeds the raw material onto the whole lenght of the hot drum. With the kneading effect of applicator rollers, raw material is spread onto the hot drum surface to form an uniform thin layer. Moisture evaporates very quicky and the drying process is finished within a single rotation of the drum. The dried product is scraped off by the blade and the vapor is sucked out by the draft fan.

Technical Parameters:

| Model | GB-600x800 | GB-800x1200 | GB-1000x1400 | GB-1200X1600 | GB-1400x1800 | GB-1800x3000 |

| Heating surface (M2) | 1.5 | 3.0 | 4.0 | 6.0 | 8.0 | 16.5 |

| Evaporation rate | 20-25 kg water/M2/hr | |||||

| Max working pressure | 1.0 MPA | |||||

| Drive motor (KW) | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 |

| Rotation speed (RPM) | 0-8 | 0-8 | 0-8 | 0-10 | 0-10 | 0-12 |

| Dimension (cm) | 170x80x150 | 250x110x180 | 280x130x190 | 320x150x220 | 360x170x230 | 480x220x250 |

| Gross weight (KG) | 850 | 1700 | 2100 | 2800 | 5500 | 8000 |

Note: Our GB Scraper Roller Dryer is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Top-feed Roller Dryer is customized according to specific raw material, drying capacity, heating medium etc . The following information is needed to work out a detailed quote:

1) Raw material name, viscosity, flowability etc. Samples might be needed for trial production or drying tests.

2) Moisture content before drying; target moisture content in dried product;

3) Required drying capacity/input in kg/h;

4) Heating medium: steam, hot thermal oil, hot water etc.

5) Suggested drying temperature

6) Power supply type: 220V/380V/415V/440V, 50/60Hz, three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 40-50 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy