LB Lump Breaker ( also called Lump Crusher or De-clumper ) is used to crush various lumps or agglomerates to obtain free-flowing material with uniform size distribution before blending, conveying or packing.

LB Lump Breaker ( also called Lump Crusher or De-clumper) is a high-efficient size reduction equipment for various lumps or agglomerates formed during storage, transportation, drying or blending. It's commonly used to crush lumps or agglomerates to obtain free-flowing material with uniform size distribution before blending, conveying or packing.

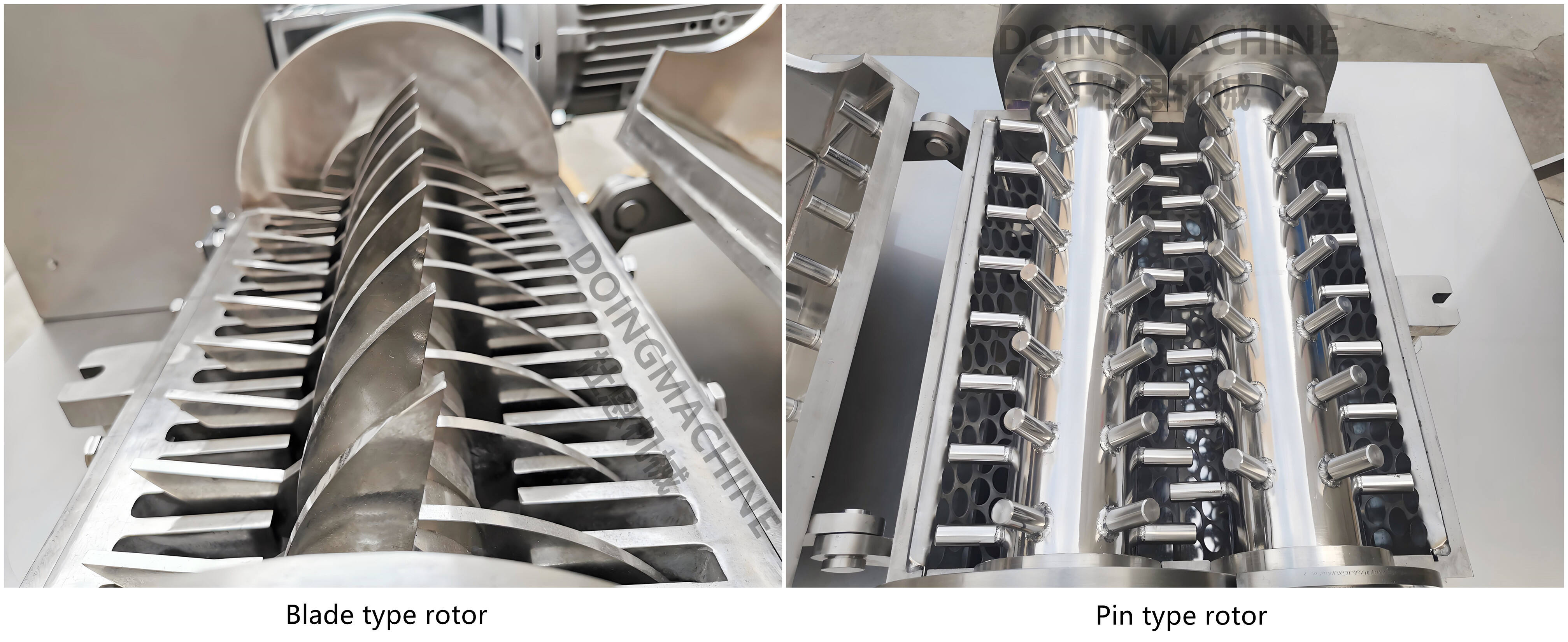

LB Lump Breaker consists of a square crushing chamber with fixed comb-type blades installed at the two sides and a horizontal rotor installed with specially designed choping blades. The fixed and rotating blades are well intermeshed to provide consistent impact and shear effect on the lumps. Sizing screen (or sieve) is installed beneath the rotor to control the product size.

Technical Parameters:

| Model | LB-150x150 | LB-250x250 | LB-250x400 | LB-400x500 |

| Crushing chamber (mm) | 150x150 | 250x250 | 250x400 | 400x500 |

| Rotor type | Single-shaft | Single-shaft | Single-shaft | Double-shaft |

| Motor power (KW) | 1.5 | 2.2 | 3 | 4 |

| Sieve hole size (mm) | 3-20 | 3-20 | 3-20 | 3-20 |

| Rotation speed (RPM) | 0-400 | 0-400 | 0-400 | 0-400 |

| Process capacity (kg/h) | 50-200 | 100-300 | 150-500 | 200-1000 |

| Gross weight (KG) | 150 | 250 | 350 | 500 |

Note: LB lump breaker is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Lump Breaker is customized. The following information is needed to work out a detailed quote:

1) Name of raw material; Lump size and hardness. Samples might be needed for tests.

2) Required product size and process capacity in kg/h;

3) How to feed the lump breaker? And the required discharge height;

4) Power supply type: 220V/380V/415V/440V, 50/60Hz, Single/three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy