Then China KJG series sewage sludge paddle dryer from DOINGMACHINE is exactly what you need if you are shopping for a powerful and dependable solution for drying sewage sludge. This effective device was designed to manage big volumes of waste products, reducing moisture content and making a top-quality end item.

It comes with a high-speed agitator that guarantees uniform mixing through the entire drying method. This assists in order to avoid the forming of lumps or clumps which could cause uneven drying. The agitator additionally helps lessen the number of power needed, since it helps circulate temperature evenly through the product.

The device was manufactured having a double-pipe framework making certain the heating medium remains split through this product while being dried up. You can stop contamination and helps to ensure that your end item satisfies the greatest criteria of purity. The unit can be loaded with an automated cleansing, enabling you to clean and sanitize the product quickly between batches.

The China KJG series sewage sludge paddle dryer is the perfect solution for you if you are working together with municipal sewage sludge, commercial waste or agricultural by products. This revolutionary product was created for the most challenging drying jobs with simplicity along with its high-capacity design and high-efficiency home heating. Plus, its lightweight size and easy-to-use settings allow it to be a fantastic choice for almost any commercial environment.

1. Continuously drying of sewage sludge, animal manures and industrial sludges;

2. Heating area: 10-200 M2

3. Evaporation capacity: 60-2000 kg/h

4. Vapor tight or vacuum designs are available

5. Heat source: steam, hot water or hot thermal oil

Model |

KJG-10 |

KJG-30 |

KJG-40 |

KJG-60 |

KJG-80 |

KJG-100 |

Heat transfer area M2 |

10 |

30 |

40 |

60 |

80 |

100 |

Evaporation rate kg/M2/hr |

6-10 |

6-10 |

6-10 |

6-10 |

6-10 |

100 |

Working temperature oC |

80-250 |

80-250 |

80-250 |

80-250 |

80-250 |

80-250 |

Shaft rotation speed RPM |

1-7 |

1-7 |

1-7 |

1-7 |

1-7 |

1-7 |

Jacket working pressure MPA |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

KJG-100 paddle dryer in Holand

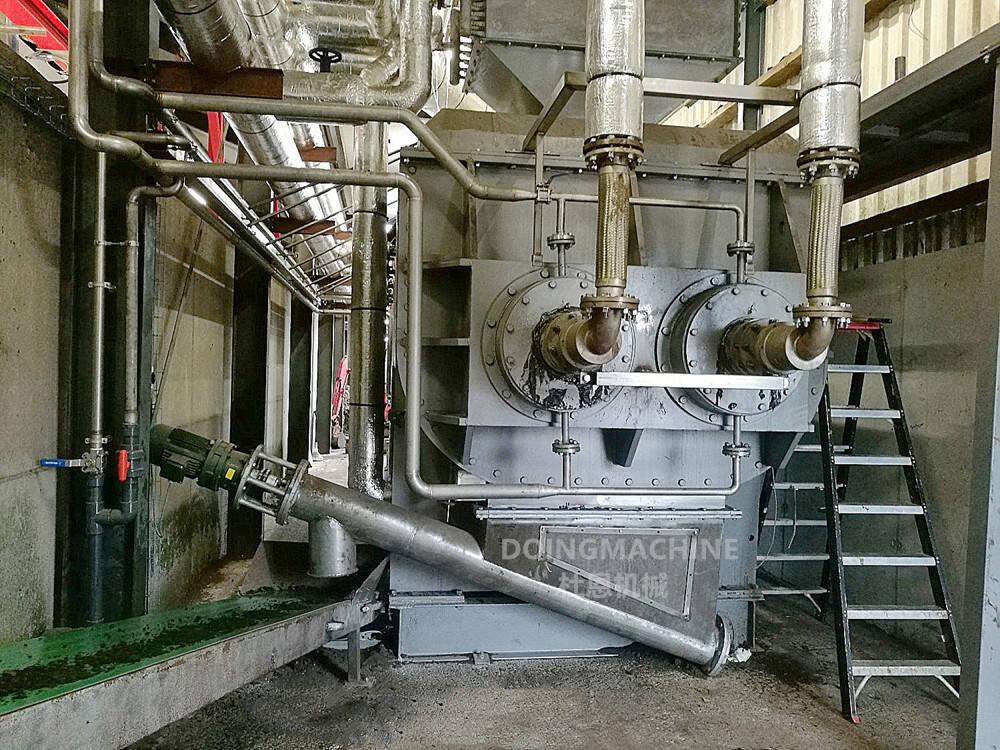

Two KJG-120 dryers in China

KJG-100 paddle dryer in Poland

Two KJG-150 dryers in China

KJG-26 paddle dryer in China

KJG-100 Paddle dryer in UK

Copyright © Changzhou Doing Machine Co., Ltd All Rights Reserved | Blog | Privacy policy