DSH nauta conical screw mixer is a convective batch mixer which is specially designed for gentle mixing of free-flowing powders or segregative pastes, slurries and liquids.

DSH nauta conical screw mixer is a convective batch mixer which is specially designed for gentle mixing of free-flowing powders or segregative pastes, slurries and liquids. It is famous for it's low-intensity mixing and highest level of mixing accuracy without product distortion.

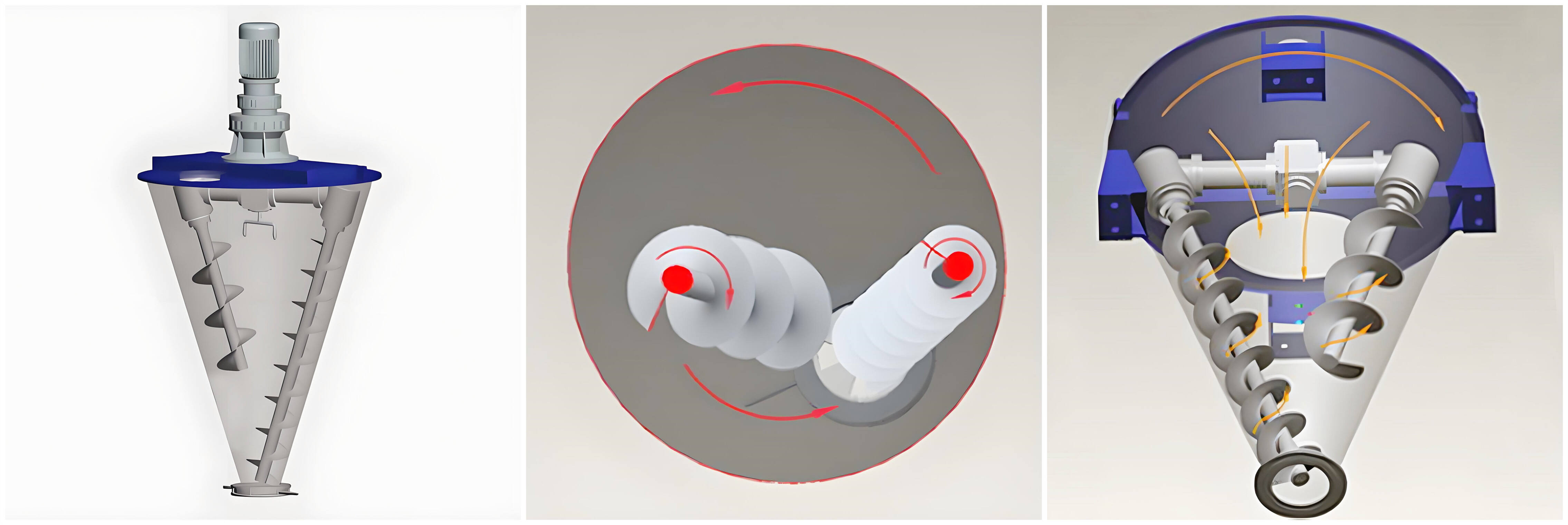

The basic design consists of two cylindrical screws located at the vessel wall that conveys product from the bottom of the conical vessel to the product surface. The twin-screw is attached to an arm which rotates around the perimeter of the vessel causing convective mixing and shear. The speed of particles in the downward massflow when recirculated by gravity in a conical vessel increases as the vessel diameter decreases. The three actions result in a unique three dimensional mixing action.

Technical Parameters:

| Model | DSH-300 | DSH-500 | DSH-1000 | DSH-2000 | DSH-3000 |

| Mixing vessel volume (L) | 300 | 500 | 1000 | 2000 | 3000 |

| Max load capacity (kg/batch) | 150 | 250 | 500 | 1000 | 1500 |

| Mixing motor (KW) | 3 | 4 | 5.5 | 7.5 | 11 |

| Rotation speed (RPM) | 2/68 | 2/68 | 2/57 | 2/57 | 2/57 |

| Dimension (mm) | Φ990x2000 | Φ1150x2300 | Φ1600x2750 | Φ1950x3400 | Φ2175x3600 |

| Gross weight (KG) | 400 | 550 | 1200 | 1500 | 2300 |

Note: DSH Nauta Conical Screw Mixer is available in many sizes. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Nauta Conical Screw Mixer is customized. The following information is needed to work out a detailed quote:

1) What raw materials you are going to mix. Raw material sample might be needed for trial production or tests;

2) Raw material bulk density and particle size

3) Load capacity in kg/batch or L/batch

4) Whether heating, cooling or liquid spraying is needed

5) Power supply type. 220V/380V/415V/440V, 50/60Hz, three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy