QZL Marumerizer Spheronzer is used to convert wet cylindrical extrudate or moist granules into spherical pellets of 0.5-5mm in diameter.

QZL Marumerizer Spheronzer is used to convert wet cylindrical extrudate or moist granules into spherical pellets of 0.5-5mm in diameter. The process is well known and widely used in the pharmaceutical, nutraceutical, catalyst, petrochemical, materials science and other industries.

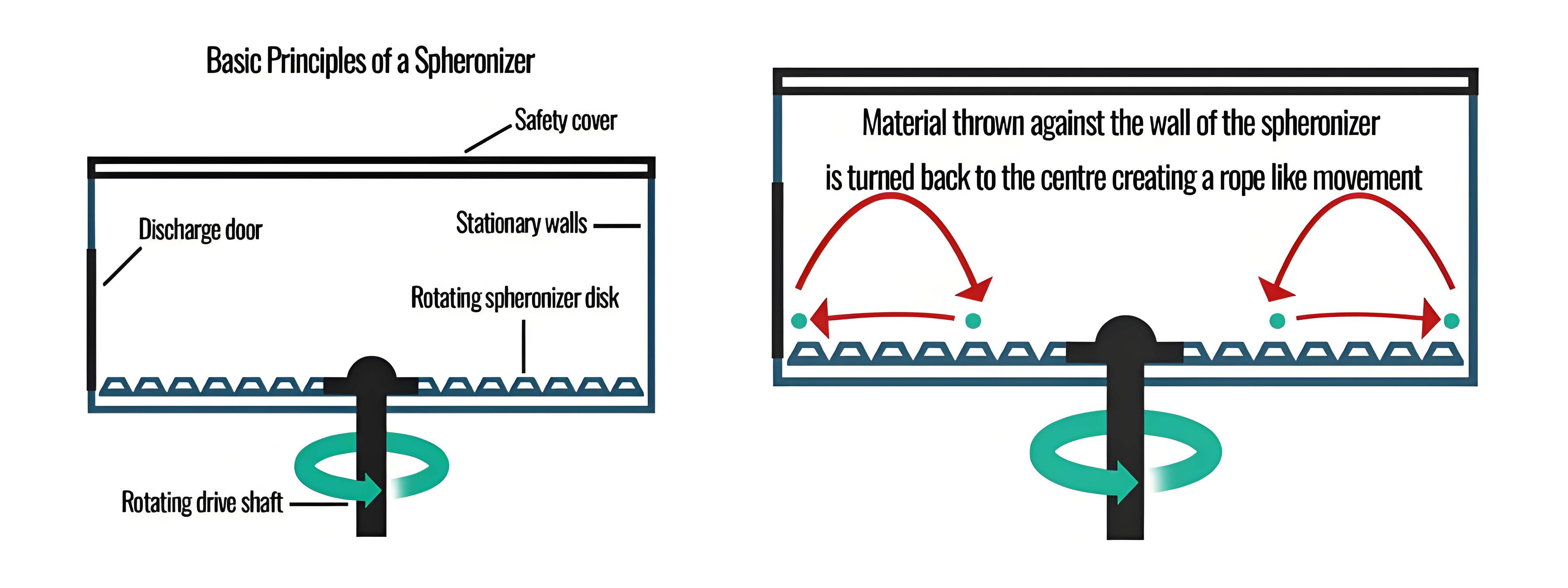

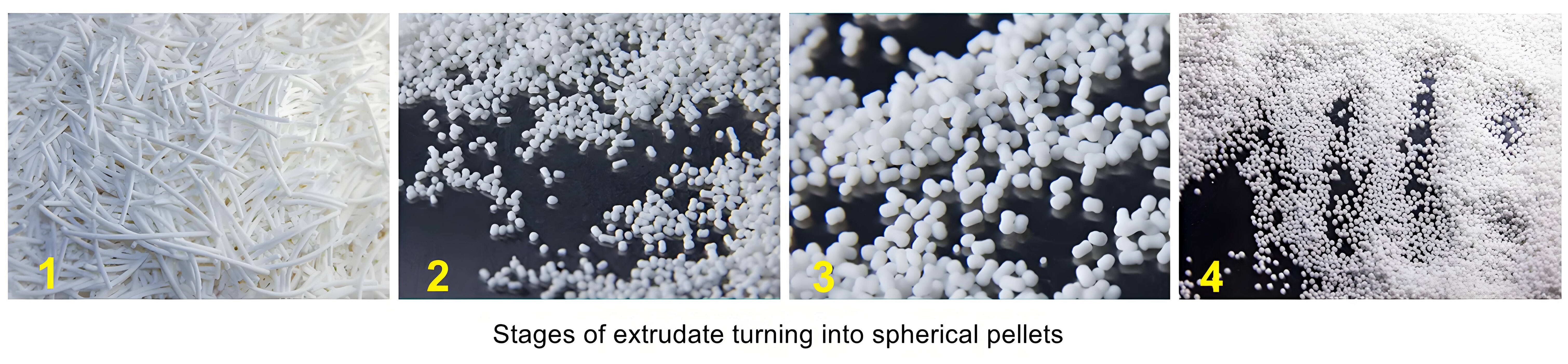

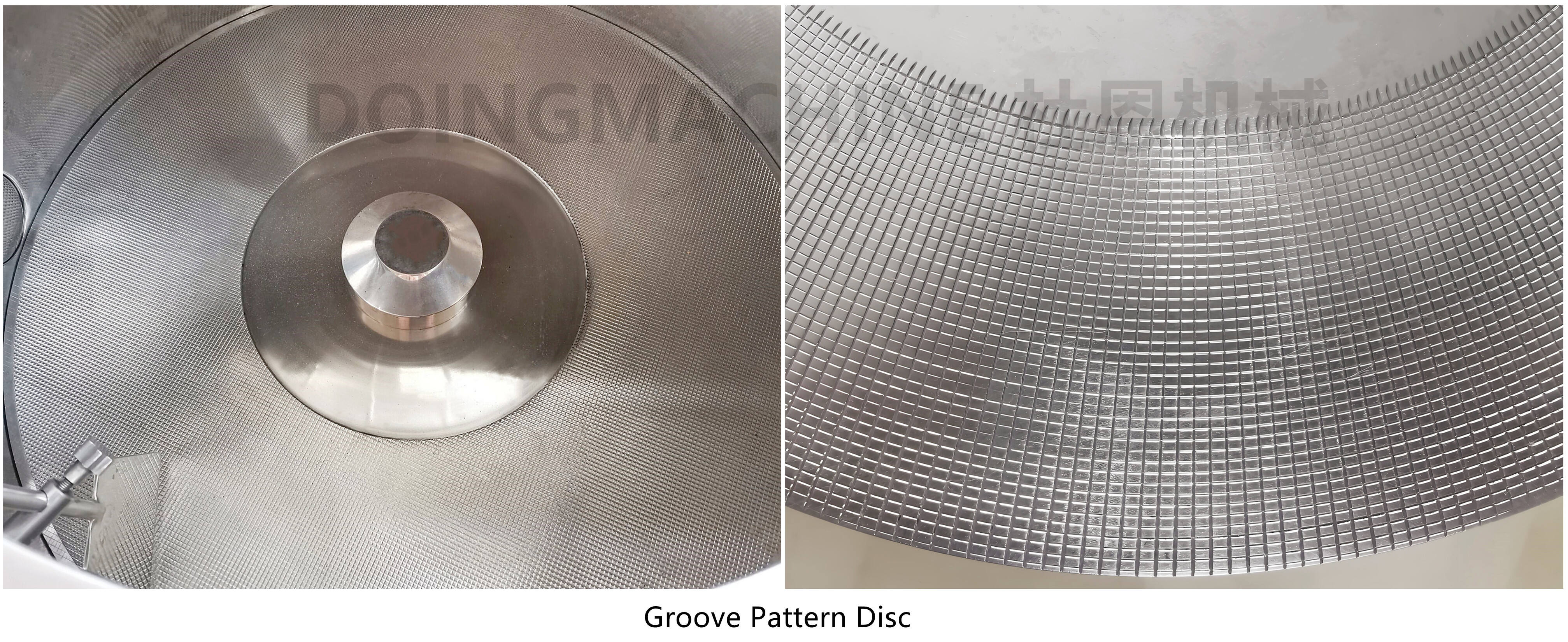

The spheronizer consists of three basic parts: cylindrial bowl with discharge port, friction disc and variable speed drive shaft. Wet cylindrical extrudate (from screw extruder or basket granulator) or moist granules (from high shear mixer granulator) are fed onto the spinning friction disc, which throw them against the inner wall of the cylindrial bowl. The extruate quicky breaks into segments of 1-1.2 times their diameter in length. These segments repeatedly collide with the bowl wall and then are thrown back to the inside of the friction disc. This ongoing process creats a "rope movement" of product along the ball wall and gradually convert the cylindrical segments into compacted spherical pellets.

Technical Parameters:

| Model | QZL-300 | QZL-500 | QZL-700 | QZL-1000 | QZL-1300 |

| Disc dia. (mm) | 300 | 500 | 700 | 1000 | 1300 |

| Capacity (kg/h) | 5-10 | 10-30 | 40-100 | 100-200 | 150-300 |

| Drive motor (KW) | 1.1 | 2.2 | 3 | 5.5 | 7.5 |

| Blower fan (KW) | 0.2 | 0.37 | 0.4 | 0.55 | 0.75 |

| Rotation speed (RPM) | 50-1000 | 50-1000 | 50-800 | 50-600 | 50-600 |

| Dimension (cm) | 100x45x70 | 120x65x70 | 150x85x100 | 180x120x110 | 200x150x120 |

| Weight (KG) | 100 | 250 | 350 | 550 | 850 |

Note: QZL Marumerizer Spheronzer is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our marumerizer spheronizer is customized. The following information is needed to work out a detailed quote:

1) What product you are going to make. Raw material sample might be needed for trial production or tests;

2) Required spherical pellet size and production capacity in kg/h;

3) Power supply type: 220V/380V/415V/440V, 50/60Hz, Single/three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy