PTFE Sintering Oven (also called PTFE Sintering Furnace) is high-temperature batch oven for sintering Teflon / PTFE products, such as Teflon parts, plate, bar and PTFE coated pipes or valves etc.

With many year's experiences, we design, manufacturer and trade good quality industrial PTFE/Teflon sintering ovens with affordable price.

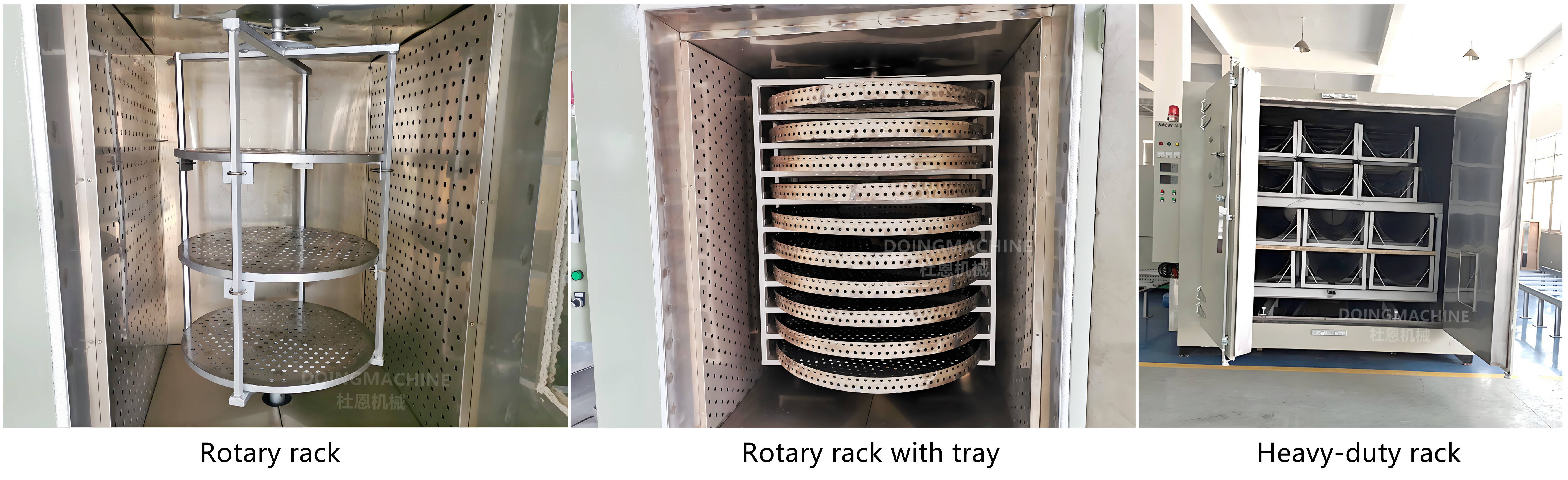

PTFE Sintering Ovens (also called PTFE Sintering Furnace) are high-temperature batch ovens for sintering Teflon / PTFE products, such as Teflon parts, plate, bar and powder coating pipes/valves etc. The part(s) to be heated are brought into the oven in batches on racks, carts, or trucks. Production requirements can accommodate manual or automated loading.

Standard batch ovens are offered in many sizes, with multiple options available upon request. And we also supply custom engineered batch ovens.

| Oven working space | Standard size or as per client requirement |

| Construction material | Mild steel; SUS304 or any |

| Working temperature range | Ambient +10 ℃ to 450 ℃ |

| Air-flow pattern | Horizontal / vertical / combination |

| Temp. control accuracy | ±1℃ |

| Temp. uniformity | ±2℃ |

| Heat-up rate | RT-400 ℃ in 30 minutes |

| Timer | Digital pre-settable HS48S-99.99 |

| Paint | Enamel paint / Epoxy coating / powder coated |

| Power supply | 240V/380V/415V; 50Hz/60Hz; 3 phase |

| Heating elements | Sheathed heating elements / SS tube |

| Insulation material | Ceramic wool |

| Door seal gasket | Fibre glass rope |

| Heavy-duty rack/cart/tray | Designed according to product size, quantity and working condition |

| Exhaust manual or automatic | Automatic forced exhaust system with fresh air inlet

Manually adjustable damper with fresh air inlet

|

| Heat source | Electric or gas |

| Temperature control | PID with SSR/SCR for high accuracy

With 40 programable heat-up rates

|

| Temperature recorder (Optional) | Microprocessor chip-based paper less, multi-stage temp. indicator cum recorder |

| PLC with HMI ( Optional) | PLC can be provided for automation and integration of the whole system, data feeding, process display and fault indication can be seen in HMI |

| SCADA system (Optional) | High quality integration and controlling system from one point can be done with SCADA |

| Door (Optional) | 1) Door interlocked with fan and heater for safty

2) Doors on both ends

3) Vertical lift door

|

| Windows and lights | 1) Viewing window

2) Interior light and access ports for calibration

|

| Timer and alarm | 1) 24/7 timer

2) APT/AD16 audible / visual alarm indicators

|

Note: Please refer to the following table for specifications of standard models.

Technical Parameters:

| Model | DM-1 | DM-2 | DM-3 | DM-4 |

| Working space (mm) | 800x800x1000 | 1000x1000x1000 | 1200X1200X1200 | 1400X1400X1400 |

| External dimension (mm) | 1100x1560x1800 | 1300X1760X1800 | 1500X1960X1900 | 1700X2160X1900 |

| Tray diameter (mm) | 700 | 900 | 1100 | 1200 |

| Electric heater (KW) | 14 | 16 | 18 | 20 |

| Circulation fan (KW) | 0.75x2 | 0.75x2 | 0.75x2 | 0.75x2 |

| Working temperature (℃) | RT-10 to 450 | |||

| Power supply | 240/380/415/440V;50/60Hz; 3 phase | |||

Note: Our PTFE Sintering Oven is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our PTFE sintering oven is customized according to the size and weight of PTFE parts. The following information is needed to work out a detailed quote:

1) Size and weight of PTFE parts?

2) Required working space and load capacity?

3) How to load the parts into the oven?

4) What heat source will be used for heating? Electricity or gas/oil fired hot air generator.

5) Power supply type. 220V/380V/415V/440V, 50/60Hz, three phase.

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 40-50 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy