Pin Mill (also called Universal Mill) is the most commonly used impact mill for fine grinding of friable or brittle raw materials; crushing flakes or agglomerates into narrow particle size range.

Pin Mill (also called Universal Mill) is high speed impact mill capable of fine size reduction of friable or brittle raw materials with medium hardness (less than 3 Mohs). The grinding chamber consists of an outer stationary disc with circular rows of pins that intermeshing with concentric rows of pins on the inner rotating disc.

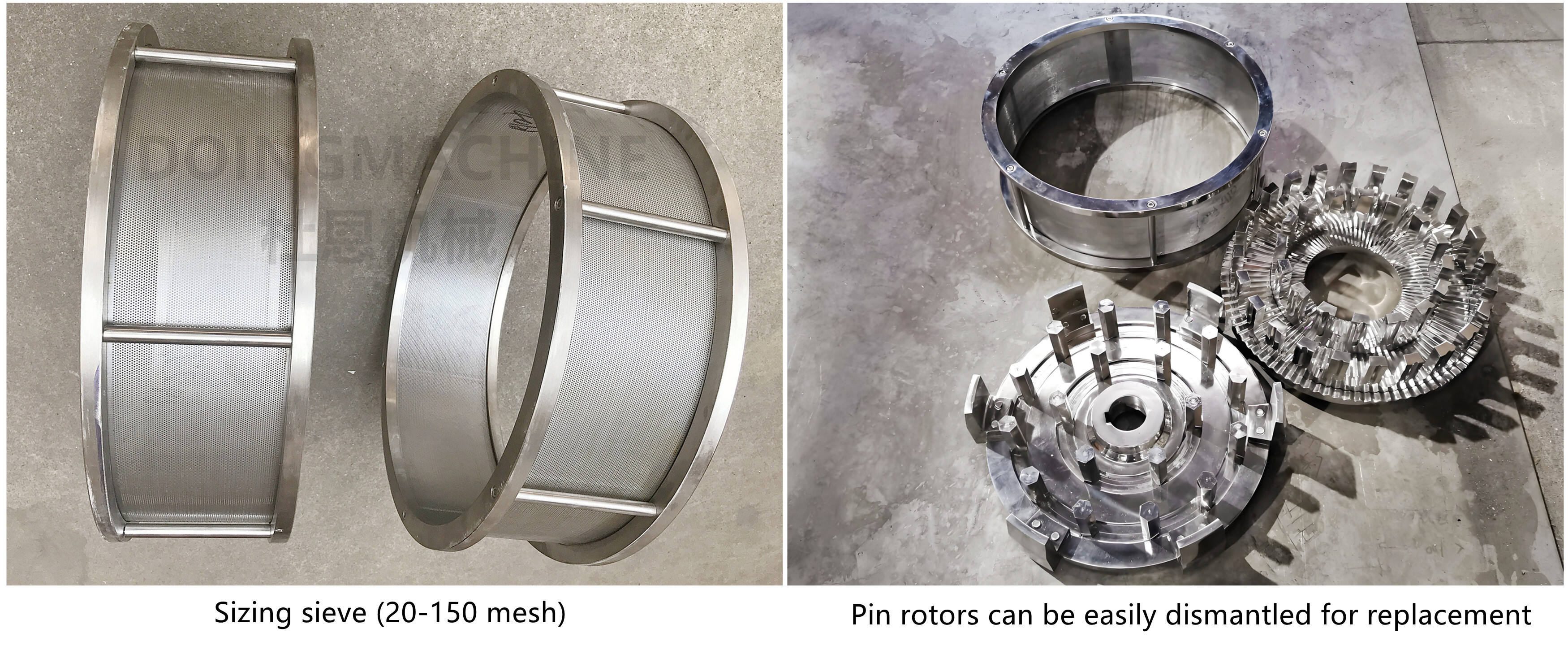

Raw material is fed into the grinding chamber via the central inlet of the opposing stationary disc by gravity or screw feeder. High speed rotation of the inner disc creates centrifugal force that accelerates bulk material moving from the center to the periphery of the discs at high speed. As materials pass through a path of intermeshing rows of rotating and stationary pins, grinding is done by strong impact and shearing between the pins. The centrifugal force or air stream generated by draft fan force the product go through a filtering sieve which is around the grinding chamber to get required particle size. Different particle size is determined by the speed, number, type of pins and hole size on the sieve.

Pin Mill is the most commonly used impact mill for fine grinding of friable or brittle raw materials; crushing flakes or agglomerates into narrow particle size range. Some typical applications are: crystal sugar, salt, gypsum, hydrated lime, chemicals, minerals, food ingredients etc.

Typical Pin: The pins have sharp edges to offer strong impact and shear simultaneously. It can be used for grinding friable raw materials, as well as low-firbous or low-oily raw materials, such as grains, beans, seasonings etc.

Round pin: Specially designed for grinding friable raw materials into super fine powder with low energy consumption, such as crystal sugar, salt, minerals, agrochemicals etc.

Technical Parameters:

| Model | 20B | 30B | 40B | 60B | 80B |

| Feed size (mm) | ≤10 mm | ≤10 mm | ≤12 mm | ≤15 mm | ≤20 mm |

| Product size (mm) | 20-200 mesh (adjustable by changing sieve) | ||||

| Capacity ( kg/h) | 20-100 | 50-300 | 100-400 | 200-800 | 300-1500 |

| Installation power (KW) | 4 | 7.5 | 17.75 | 30.25 | 48.75 |

| Dimension (mm) | 820x650x1500 | 900x700x1650 | 6250x1350x2900 | 7400x1450x3150 | 7900x1600x3250 |

| Weight (KG) | 250 | 350 | 1350 | 1650 | 2100 |

Note: Our Pin Mill is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Pin Mill is customized. The following information is needed to work out a detailed quote:

1) What raw material you are going to grind. Raw material sample might be needed for trial production or tests;

2) Raw material size;

3) Required product size;

4) Process capacity in kg/h;

3) Power supply type: 220V/380V/415V/440V, 50/60Hz, Single/three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy