Horizontal Ribbon Blender is high-capacity batch mixer for fast and intimate mixing of dry, free-flowing solids.

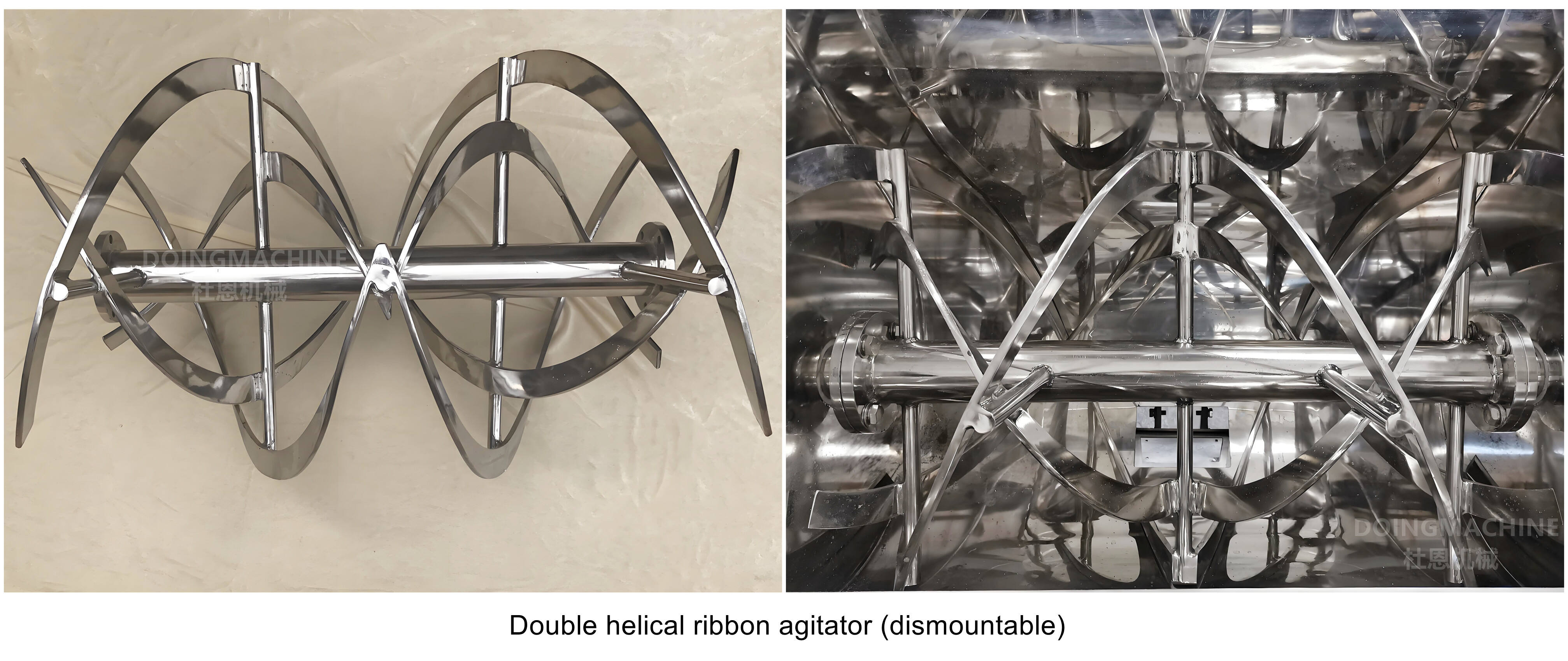

Horizontal Ribbon Blender is high-capacity batch mixer for fast and intimate mixing of dry, free-flowing solids. Ribbon blender consists of a U-shaped horizontal trough and a solid agitator shaft with inner and outer helical blades called ribbons. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction.

Raw materials are fed into the mixing vessel via the top feed port manually or by screw conveyor. The loading rate can be 50-70% of the mixing vessel volume. Through mechanical transmission, the ribbon agitator rotates at approx 45 RPM which moves materials both both radially and laterally to insure homogeneous blending in short cycle times. The mixed product is discharged via the pneumatic flap valve installed on the bottom center of the mixing vessel.

Horizontal Ribbon Blender is comonly used to produce homogeneous solid-solid mixture for industries such as food, cosmetics, pharmaceutical, chemical, nutritional, agrochemical and plastics. It also can be used to mix solids with small proportion of liquid to prepare low-density, free-flowing wet mixture.

Technical Parameters:

| Model | WLDH-300 | WLDH-500 | WLDH-1000 | WLDH-1500 | WLDH-2000 | WLDH-3000 |

| Mixing vessel volume (L) | 300 | 500 | 1000 | 1500 | 2000 | 3000 |

| Working volume (L) | 180 | 300 | 600 | 900 | 1200 | 1800 |

| drive motor (KW) | 4 | 7.5 | 11 | 15 | 15 | 18.5 |

| Rotation speed (RPM) | 65 | 65 | 48 | 48 | 35 | 35 |

| Installation dimension(cm) | 190x68x100 | 250x80x125 | 290x95x135 | 310x98x150 | 330x105x160 | 360x125x185 |

| Gross weight (KG) | 600 | 900 | 1300 | 1600 | 2000 | 2600 |

Note: Our Ribbon Blender is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Horizontal Ribbon Blender is customized. The following information is needed to work out a detailed quote:

1) What raw materials you are going to mix. Raw material sample might be needed for trial production or tests;

2) Raw material bulk density and particle size

3) Load capacity in kg/batch or L/batch

4) Power supply type: 220V/380V/415V/440V, 50/60Hz, Single/three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy