LGH High Speed Mixer is vertical batch mixer, which is used for fast mixing of dry powders with liquids to make highly homogeneous wet mass.

LGH High Speed Mixer is vertical batch mixer, which is used for fast mixing of dry powders with liquids to make highly homogeneous wet mass for extrusion. It also can be used for high shear granulation when binder is added.

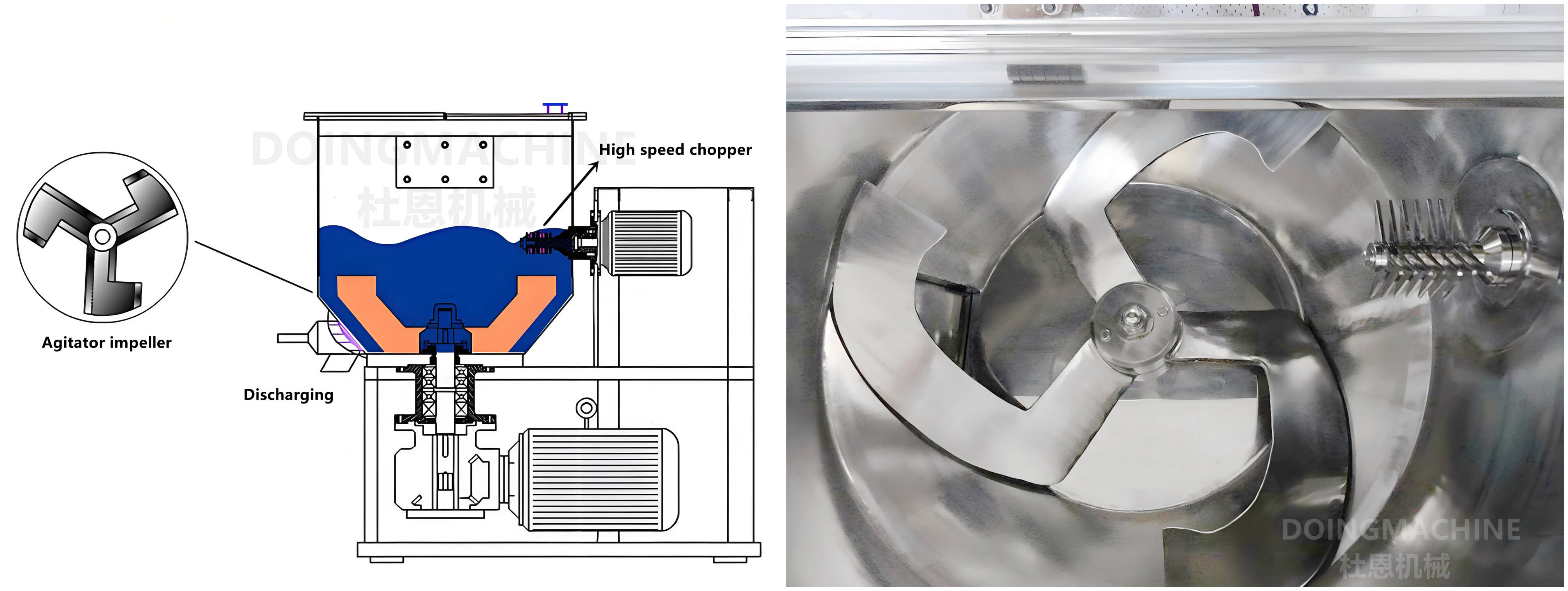

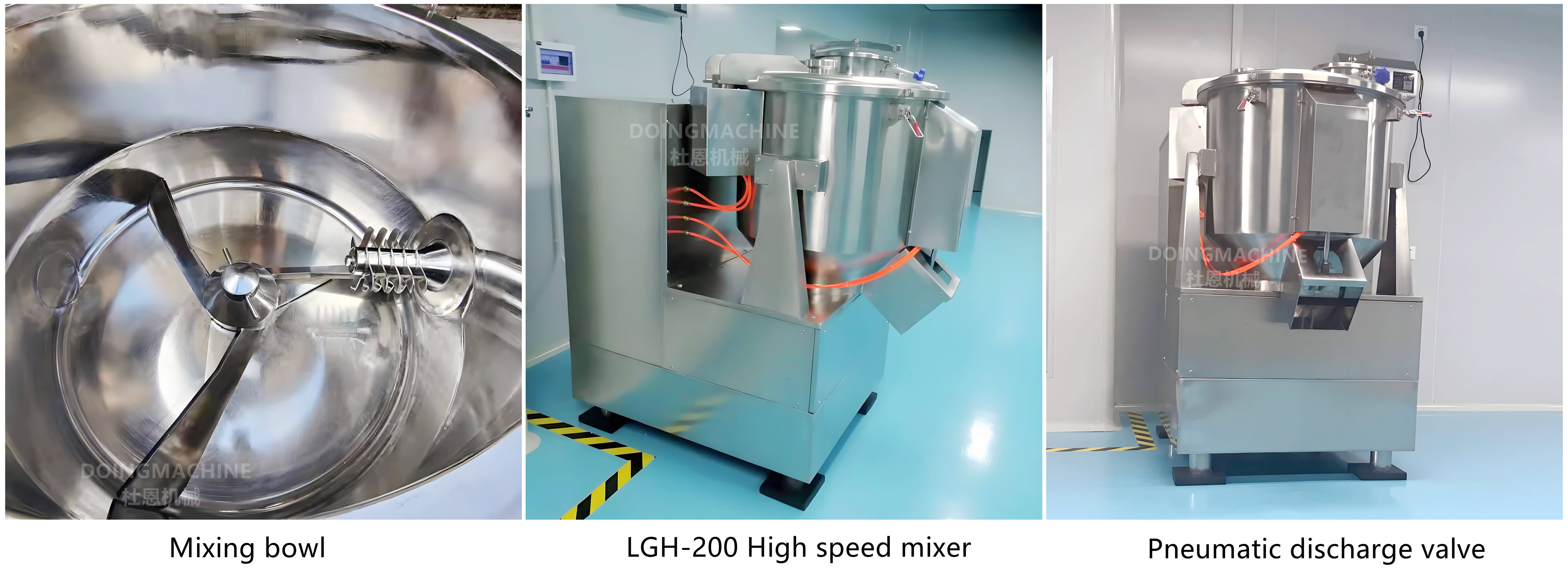

LGH High Speed Mixer consists of a cylindrical mixing bowl, bottom placed agitating impeller and side installed choppers. Raw materials are gravity fed into the mixing bowl, the specially designed rotating impeller pushes the material onto the inner wall. Under the effect of centrifugal force, raw materials move up alongside the inner wall to form a swirl flow. At the same time, the side installed high-speed chopper completely shear and chop the materials for fast and intimate mixing.

LGH High Speed mixer is extensively used in chemical, metallurgical, food, light and agricultural industries for small scale fast mixing with very high homogeneity. This design can carry out even mixing of powders or slurry materials with different proportion, so that the mixed materials can reach their best effectiveness.

Technical Parameters:

| Model | LGH-100 | LGH-200 | LGH-300 | LGH-400 | LGH-500 |

| Mixing bowl volume (L) | 100 | 200 | 300 | 400 | 500 |

| Load capacity (kg/batch) | 30-40 | 60-80 | 90-120 | 120-160 | 150-200 |

| Mixing motor (KW) | 5.5 | 11 | 15 | 22 | 30 |

| Chopper motor (KW) | 3 | 4 | 5.5 | 7.5 | 7.5 |

| Dimension (mm) | 1000x600x1200 | 1100x700x1250 | 1250x800x1350 | 1350x900x1350 | 1350x1000x1350 |

| Gross weight (KG) | 200 | 300 | 400 | 600 | 800 |

Note: Our LGH High Speed Mixer is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our High Speed Mixer is customized. The following information is needed to work out a detailed quote:

1) What raw materials you are going to mix. Raw material sample might be needed for trial production or tests;

2) Raw material bulk density and particle size

3) Load capacity in kg/batch or L/batch

4) Power supply type. 220V/380V/415V/440V, 50/60Hz, three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy