HPG Heat Pump Sludge Dryer is ideally suited for low temperature drying of various kinds of sludge or biosolids with super low energy consumption.

Working Principle and Applications:

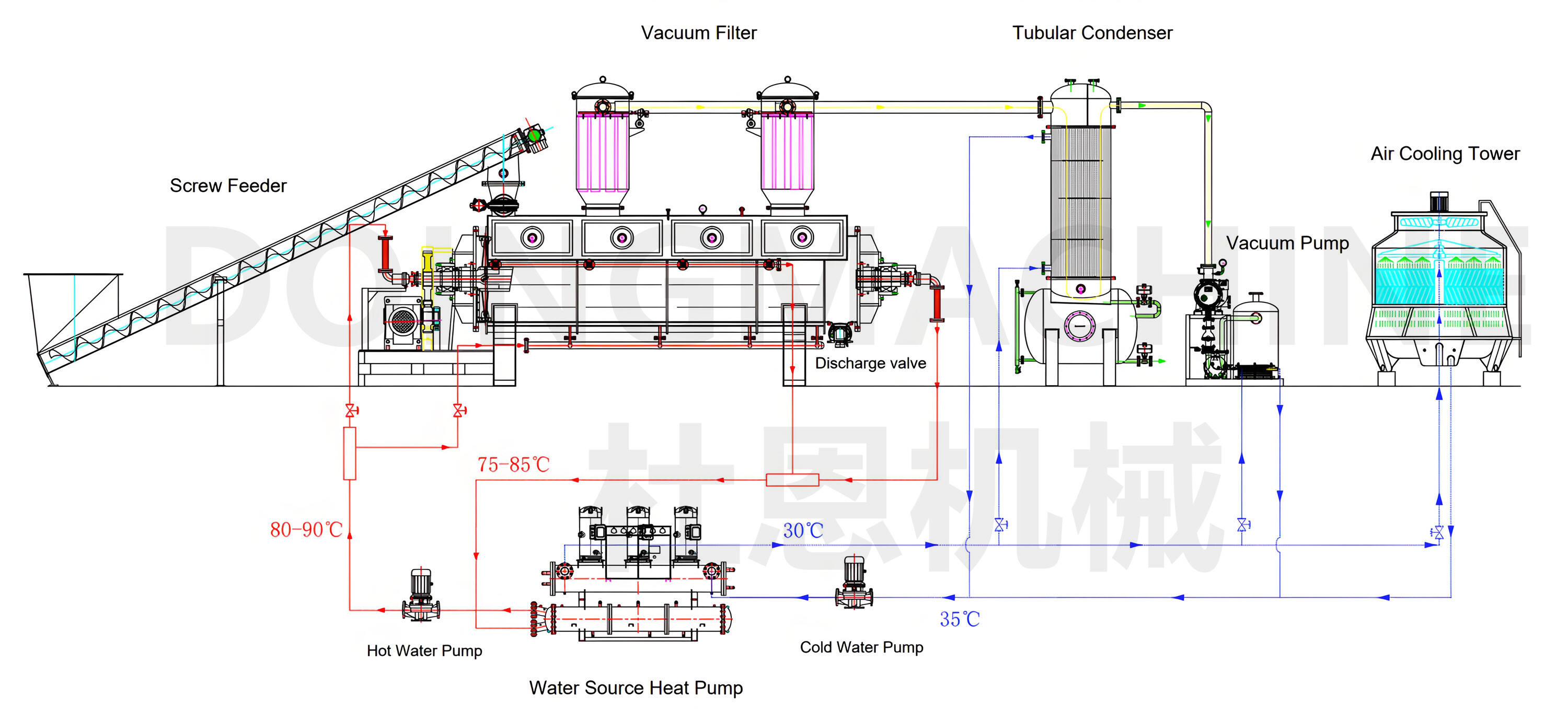

Working principle: HPG Heat Pump Dryer combines vacuum drying and heat pump techonologies into one drying system to achieve overwhelming advantages in energy efficiency. The apply of vacuum drying is to lower the boiling point of water or solvents contained in wet material, which makes low-temperature drying feasible and high-efficient; water souce heat pump can generate 80-90 ℃ hot water for drying with COP (Coefficient of Performance) of 2.8-3, while the cool source water is forced to circulate inside the tubular condenser and vacuum pump for cooling process. The heat recovered from the vapor and vacuum pump makes the drying process sustainable.

The combined dryer is Vacuum Disc Dryer, which consists of a jacketed cylindrical vessel and a hollow shaft fitted with double-walled discs to considerablly increase heating surface. Hot water (80-90 ℃) from heat pump is forced to circulate both inside the jacket and hollow discs to form heating surface. Agitator paddles are welded on the disc peripheries with different angles to mix and move the wet material for uniform heating. Scraper bars are installed between the discs to prevent wet material from sticking to the discs and crush the lumps.

Wet material is gravity fed into the drying chamber via the infeed port with screw feeder, then vacuum and heat are applied to reach the evaporation point of water or solvents contained in wet material. Meanwhile, the disc rotor rotates in different directions to completely mix, move and break the wet material for fast and uniform heat transfer. Moisture evaporates rapidly and is extracted as vapor by the vacuum pump. Tubular condenser is installed to recover the evaporated moisture. The drying process can be batch or continuous operation.

Applications: HPG Heat Pump Dryer is ideally suited for low temperature drying of wet powders, filter cakes, sticky pastes or slurry materials in various industries with the following special features:

1) Heat sensitive and/or oxygen sensitive

2) Contained solvents and need to be recovered

3) Hazardous and/or smelly wet materials (has to contain the release of pollutive substances)

Technical Features:

Typical Models

| Model | HPG-1000 | HPG-2000 | HPG-4000 | HPG-6000 | HPG-8000 | HPG-10000 | HPG-12000 |

| Drying chamber volume (L) | 1000 | 2000 | 4000 | 6000 | 8000 | 10000 | 12000 |

| Max working volume (L) | 700 | 1400 | 2800 | 4200 | 5600 | 7000 | 8400 |

| Total heating surface (M2) | 12 | 24 | 50 | 70 | 90 | 110 | 130 |

| Evaporation rate | 6-8 kg water/M2/Hr | ||||||

| Vacuum degree | -0.088-0.096 Mpa | ||||||

| Heating medium | 80-90 ℃ hot water from heat pump | ||||||

Note: Our HPG Heat Pump Dryer is available in many sizes and configurations. The above models with typical design are indicative only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Heat Pump Dryer is customized according to specific wet material and drying capacity ( normally 100 kg to 3 tons/h). The following information is needed to work out a detailed quote:

1) Detailed information of wet material to be dried:

2) Initial moisture content; target moisture content in dried product;

3) Required drying capacity in kg/h;

4) Power supply type: 220V/380V/415V/440V, 50/60Hz, three phase

Q: What is your normal lead time?

A: All our dryers are customized. The normal lead time is 50-60 days after receiving the advance payment.

Q: How the dryer is delivered?

A: Rotary Vacuum Paddle Dryer is big indutrial machine and the gross weight ranges from 3 tons to 50 tons. When the heating surface is less than 60 M2, the dryer body can be shipped by 40 feet HQ container; 60-100 M2 should be shipped by 40 feet OT container; more than 100 M2, the dryer body has to be dismantled for shipping.

Q: What kind of after-sale service can you provide?

A: 1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog | Privacy Policy