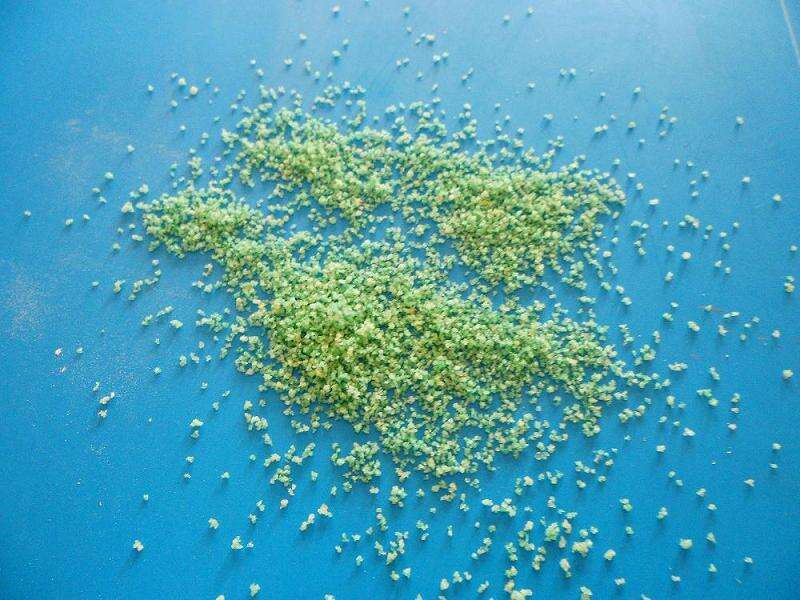

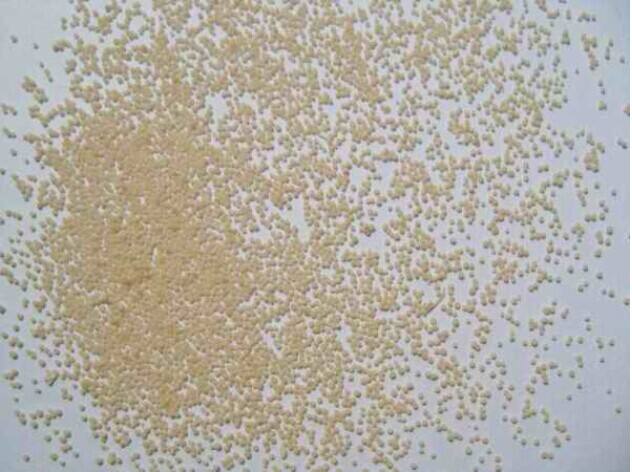

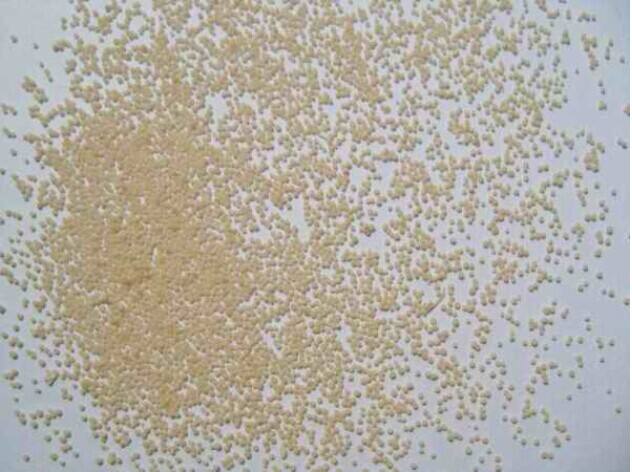

1. Powder granulation or agglomeration in Food and Chemical industry;

2. Capacity: 3-500 kg/batch;

3. GMP design;

5. Heat source: steam, electricity, thermal oil etc.

FL series fluid bed granulator is a batch type top spray powder granulation/agglomeration processor which has been widely used in pharmaceutical, chemical and foodstuff industry. Raw materil (free-flowing dry powder or small granules ) is loaded in the granulating bowl of which the bottom is made by perforated plate. Clean hot air flows through the perforated plate to completely fluidize the material. Meanwhile, liquid binder is sprayed onto the fluidized material. Fine powder collides with droples and stick together to form granules or agglomerates with good flowability and instant solubility.

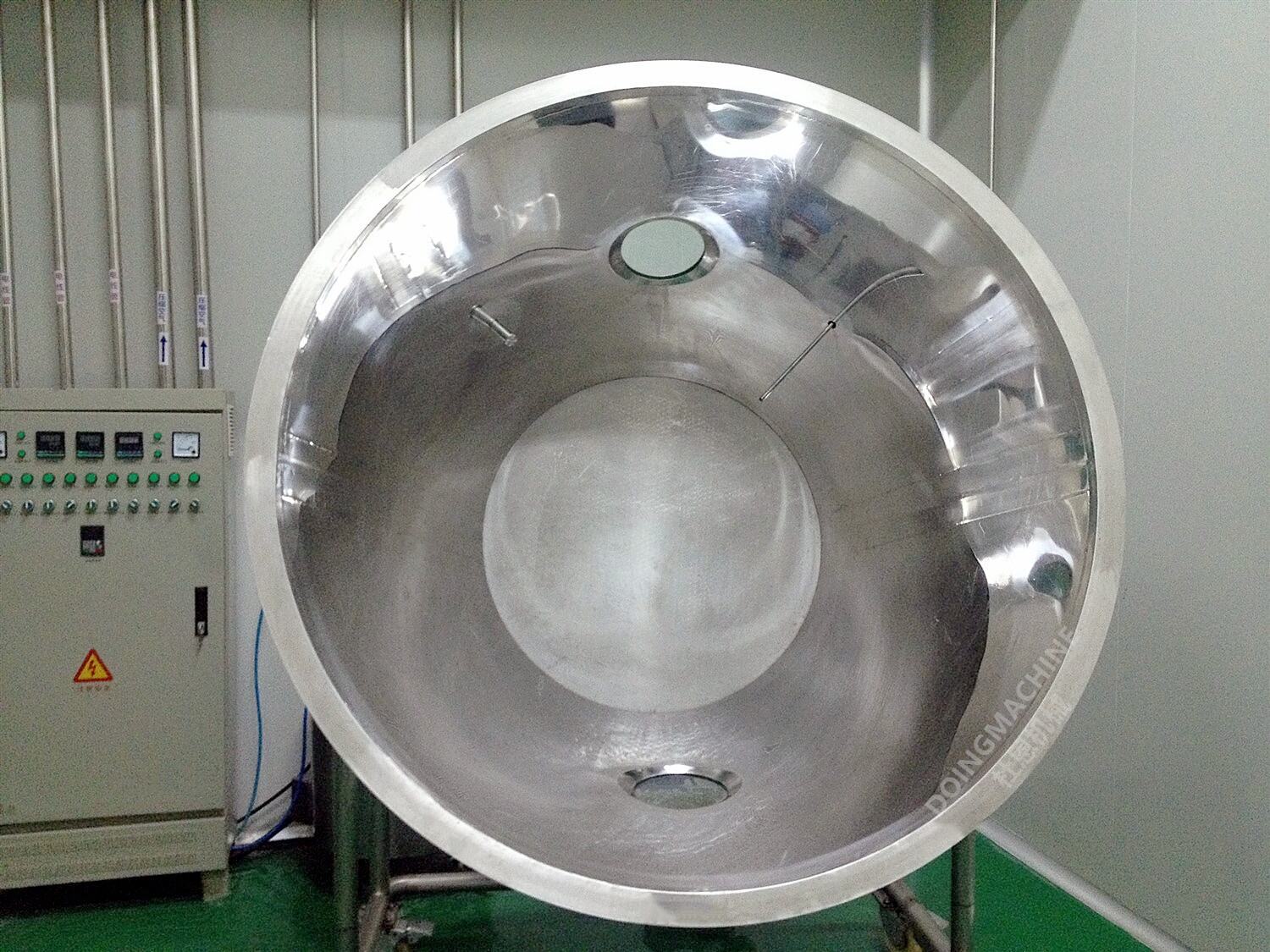

1. cGMP Design: 150 grit exterior finish, mirror finish on internal surfaces. The system can meet GMP standard;

2. HEPA air filter: The air filter consists of primary stage, secondary stage and high efficiency stage air filter and the air cleanness can reach 100,000 grade;

3. Automatic pneumatic sealing: two pneumatic cylinders lift the granulation bowl for sealing with the top chamber; the inflated square rubber ring will seal the bottom chamber to create a completely sealed granulation chamber;

4. Two-bag-filter-chamber system: The top bag filtering system has two chambers which work alternately to avoid air pressure onto the filter bag. The product rate can reach 99%.

5. Accurate air flow control: The exhaust fan is combined with Siemens inverter to accurately control the air flow rate for achieving perfect fluidization.

6. Good working condition: The whole system is working under negative pressure, so there is no powder leaking at all. Exhaust fan is equipped with silencer as well as isolated installation, the noise is below 75 dB(A).

7. Safety measures: The whole system adopts following measure to 100 % make sure safety during operation:

1) Function interlocked: All the function buttons in the control panel are interlocked (only proper operation steps can run the system) to prevent any mistakable operation to the machine.

2) Explosion proof design: Granulation chamber is equipment with venting. When the pressure inside the chamber is getting higher than the rated one (say 2 bar), the rupture membrane will break to release the pressure.

3) Pressure monitoring: Pressure sensor is equipped to monitor pressure change inside the granulation chamber. When pressure is getting higher (especially when the bag filter is choked) and positive pressure condition is formed, electrical heater and exhaust fan will stop automatically and pressure release valve will open.

Main Technical Parameters

Model |

FL-30 |

FL-60 |

FL-120 |

FL-200 |

FL-300 |

||||

Volume of drying bowl (L) |

100 |

220 |

420 |

670 |

1000 |

||||

Diameter (mm) |

700 |

1000 |

1200 |

1400 |

1600 |

||||

Loading capacity (kg/batch) |

15-45 |

30-90 |

80-160 |

100-300 |

150-450 |

||||

Exhaust fan (KW) |

7.5 |

11 |

18.5 |

22 |

30 |

||||

Steam consumption (kg/h) |

70 |

140 |

210 |

282 |

366 |

||||

Steam pressure (Mpa) |

0.3-0.6 |

||||||||

Working temperature (°C ) |

Ambient temp. -120 |

||||||||

Working time (Min) |

45-90 |

||||||||

Product collection rate (%) |

≥ 99 |

||||||||

Noise (dBa) |

≤ 75 |

||||||||

Weight (kg) |

700 |

1000 |

1300 |

1500 |

1800 |

||||

Dimension (L x W x H) M |

1.6x1.1x2.5 |

1.85x1.4x3 |

2.2x1.65x3.3 |

2.34x1.7x3.8 |

2.8x2.0x4.0 |

||||

Q: What information should be provided in order to get a proposal or quotation?

A: Our fluid bed dryer granulator can be customerized. Before we can work out a detailed quotation, we have to know the following information:

1) What product you are going to make

2) Bulk density and particle size of your product

3) Type of binder you plan to use

4) Process capacity in kg/batch

5) What heat source you plan to use; steam or electricity

6) Your required granule size

Q: How the granulator will be delivered ?

A: The dryer is packed in plywood box for shipping

Brand: DOINGMACHINE

Interested in a dependable and solution this is certainly granulation that is efficient drying requirements? Take a good look at the spray this is Top spray fluid bed dryer granulator from DOING MACHINE.

This cutting-edge spray this is certainly bed that is top granulator is perfect for an extensive volume of, including pharmaceuticals, meals, chemicals, and much more. The granulation and drying process, ensuring peak quality for the end item alongside its more impressive range technology, it provides control that is exemplary.

The spray this is certainly sleep that is top granulator was created with durable and materials being high-quality ensure its durability and dependability for a long period later. Furthermore, this fluid bed dryer granulator adopts a safety this is certainly comprehensive ensuring the security of everybody mixed up in procedure.

One when it comes to most exciting top popular top features of this spray this is certainly sleep that is top granulator is its system spray top. This method enables for exact control over the circulation regarding the solution that is granulating an extremely constant and product this is certainly consistent. Furthermore, which means the technique this is certainly drying and efficient, assisting you to truly save some right time energy.

The DOING MACHINE Top spray fluid bed dryer granulator also boasts a makes program which are user-friendly and upkeep easy and uncomplicated. The DOING MACHINE fluid rest dryer granulator is produced become used by operators out of all the skill levels with easy-to-follow directions.

Another impressive feature regarding the spray that is top bed dryer granulator is its low noise and procedure this is certainly vibration low. This decreases operator weakness and assists it's better to utilize for extended periods.

Copyright © Changzhou Doing Machine Co., Ltd All Rights Reserved | Blog | Privacy policy