Presenting the Heat pump sludge dryer drying machine. This method is fantastic for people who find themselves buying economical and method eco-friendly dry their sludge. This product makes usage of temperature pumps that run using electricity to dry your sludge by extracting dampness as a result.

The Heat pump sludge dryer drying machine is merely a device built to be easy to use. Its design compact makes easy to arranged and make utilization of in any location. It indoors or out-of-doors, this revolutionary product is very effective for you personally whether you intend to utilize. Just load your sludge in the device, set the warmth, and invite it do its work. The equipment will adjust the heat immediately and fan rate to ensure that your sludge is dried out to your degree optimal.

This device is affordable and could help you save a pile of cash to the run very long. Using a temperature pump to dry your sludge, you will not need to buy electricity costly gas bills. Which means you'll spend less all on your own power bills while nevertheless getting the working task done.

The Heat pump sludge dryer drying machine could be eco-friendly. It operates on the all system closed recycles the air in the device in the place of releasing it to the environment. Which means that it's not going to subscribe to atmosphere weather or air pollution modification.

The product includes a whole massive amount advantages. As well as being easy to use, affordable, and eco-friendly, additionally creates outcomes that can easily be top-quality. The sludge which comes using this device is dry, odorless, and safe to address. This implies to be a fertilizer in your yard without fretting you or the environmental surroundings that can be used it about it causing any injury to.

The Heat pump sludge dryer drying machine is actually a dependable and piece efficient of this you shall wind up very happy to have in your control. It is durable, and you might expect it to endure for a time very long. Furthermore, the apparatus has security features to avoid accidents and injury to the gear.

.

Main features

1. Thermal drying of various kinds of sludge/biosolids under vacuum condition;

2. Heating area: 10-300 M2

3. Evaporation capacity: 50-2000 kg/h

4. Working type: Batch or continuous

5. Heat source: 65-80 ℃ hot water from heat pump

Working Principle

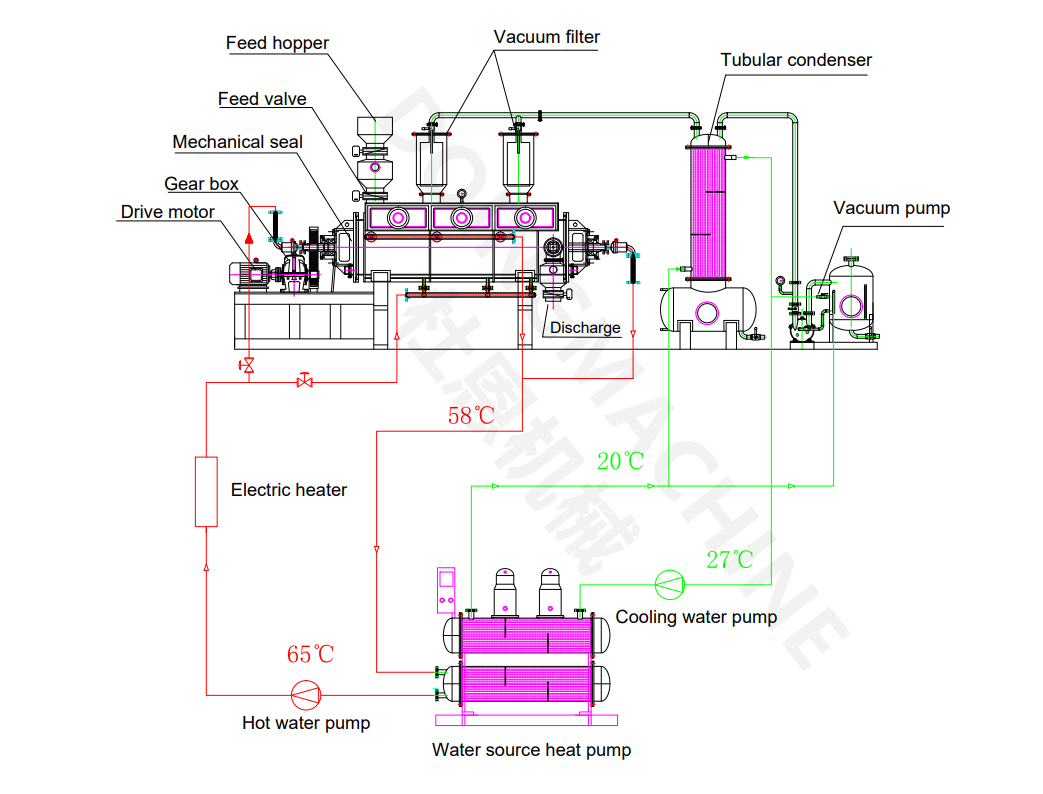

PZG series vacuum paddle dryer is indirect contact dryer under high vacuum condition to considerably reduce water boiling point. The dryer consists of a jacketed cylindrical drying chamber and a rotor fitted with hollow discs. Hot water from heat pump flows both inside the jacket and hollow discs to form heat transfer surface.

Wet material is fed into the dryer via rotary valve or sludge pump. Due to the rotation of rotor, wet material is mixed and pushed forward by the agitator paddles attached to the disc peripheries. Fixed scraper bars are installed between the disc to prevent wet material from sticking to the discs. With regular mixing, movement and heat transfer between wet material and heated surface, moisture evaporates rapidly. When wet material reaches the opposite end of the dryer, it is dried and discharged via rotary valve. The evaporated moisture is sucked out by vacuum pump and recovered by tubular condenser.

Technical advantages

Our Heat Pump Vacuum Paddle Dryer has been increasingly used for drying sewage sludge, industrial sludge, organic waste, fishmeal, feather meal etc, due to the following overwhelming advantages:

1. Low temperature drying: Vacuum degree can reach as low as 1000 pa. Water boiling point under such low vacuum is only about 45 ℃. The evaporation rate can still reach 6-8 kg water/hr/M2 when use 80 ℃ hot water for drying.

2. Super low energy consumption:The average heat consumption to evaporate 1 kg water is about 600 kcal because of high vacuum, large heating surface and little heat loss. Waste heat in the vapor can be recycled by the heat pump to further reduce energy consumption.

3. Almost zero-emission:The drying process conducts in a completely sealed system and the evaporated moisture is trapped by air-liquid separator and tubular condenser to prevent emission.

4. Batch or continuous operation:Our vacuum paddle dryer can work both in batch or continuous operation to satisfy different working conditions.

Main technical parameters

Model |

PZG-600 |

PZG-1000 |

PZG-2000 |

PZG-4000 |

PZG-6000 |

PZG-8000 |

Volume L |

600 |

1000 |

2000 |

4000 |

6000 |

8000 |

Working volume L |

420 |

700 |

1400 |

2800 |

4200 |

5600 |

Heat transfer area M2 |

6 |

10 |

20 |

40 |

60 |

80 |

Evaporation rate kg/M2/hr |

6-10 |

6-10 |

6-10 |

6-10 |

6-10 |

6-10 |

Working temp. oC |

60-280 |

60-280 |

60-280 |

60-280 |

60-280 |

60-280 |

Vacuum degree Pa |

300-1500 |

300-1500 |

300-1500 |

300-1500 |

300-1500 |

300-1500 |

Tubular heating jacket

1) Working pressure as high as 10 bars

2) 80 mm mineral insulation to prevent hot loss

3) Full-length vapor dome reduces carry-over and separates solids from the evaporated water vapor.

4) Removable covers provide easy inspection, cleaning and adjustment

Hollow disc

1) Considerably increase heating surface

2) Much less welding area than other types of paddles

3) Self-cleaning disc surface considerably enhances heat transfer

4) Agitator paddles welded on disc peripheries with different angle can perfectly mix, move and crush wet material

5) Scraper bars installed between the discs prevent wet material from sticking to the discs

Integral beating seat and mechanical sealing

1) Bearing seat is mounted on end plate as an integral part of drying chamber to ensure the concentricity of shaft.2) Water cooling jacket is equipped to increase the life-span of bearing.

3) Double-end mechanical seal is used to ensure high vacuum degree.

Vapor recovery system

The vacuum system consists of two-stage tubular condenser, separator and oilless roots vacuum pump to guarantee high vacuum degree (500-1000 pa) and recovering rate (98%).

PZG-6500 vacuum paddle dryer in Hungary

PZG-8000 vacuum paddle dryer in Poland

PZG-2000 vacuum paddle dryer in Korea

PZG-8000 vacuum paddle dryer in China

PZG-8000 vacuum paddle dryer in China

PZG-8000 vacuum paddle dryer in Canada

Q: What information should be provided in order to get a proposal or quotation?

A: Our rotary vacuum paddle dryer is specially designed for each customer according to specific wet material, capacity, drying temperature and heat mediums. Before we can work out a detailed proposal, we have to know the following information:

1) Detailed information of wet material you are going to dry. We may ask you to provide composition report or samples for drying test.

2) Type of moisture.

3) Initial moisture content before drying

4) Required moisture content in dried product

5) Drying capacity in kg/h

6) Heat medium to be used for drying. Such as steam, thermal oil or hot water

Q: How the machine is delivered ?

A: Rotary vacuum paddle dryer is very heavy and its weight ranges from 3 tons to 50 tons. When the heating area is less than 60 M2, the dryer body can be shipped by 40 feet HQ container; 60-100 M2 should be shipped by 40 feet OT container; more than 100 M2, the dryer body has to be dismantled for shipping.

Q: What kind of after sale service you can provide?

A: We have professional after sale service team who can reach you in short notice. They can supervise the installation, do commissioning and train your workers.