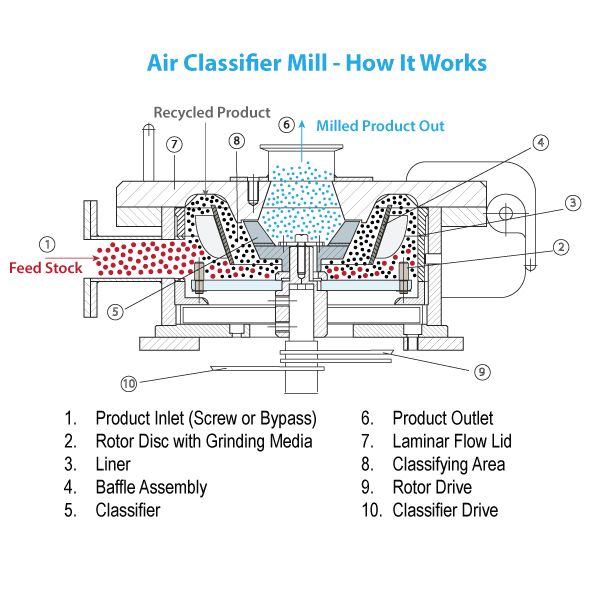

WFJ series air classifying mill pulverize are high-energy vertical grinding mills incorporating an internal air classifying wheel to control product particle size distribution.

Material is fed into the grinding chamber via screw feeder and strongly impacted and collided into fine powder between the high-speed disc rotor and teeth liner. After grinding process, fine powders are carried to the classifying section by airflow where qualified powders are suctioned into the interior of the classifying wheel and discharged as products; coarse powders flow through the inner guide ring back to the grinding chamber because of centrifugal force for re-grinding. Final product is collected by cyclone and bag house.

WFJ series air classifying mill pulverize has been widely used for milling/pulverizing high fiber content materials, heat sensitive materials and brittle materials in food and chemical industry.

Model |

WFJ-15 |

WFJ-20 |

WFJ-30 |

WFJ-60 |

Capacity kg/h |

10-200 |

20-400 |

30-800 |

50-1200 |

Input size mm |

≤10 |

≤12 |

≤12 |

≤12 |

Output size mesh |

80-350 |

80-350 |

80-350 |

80-350 |

Total power KW |

13.5 |

22.5 |

46 |

84.15 |

Rotation speed RPM |

5800 |

5800 |

3800 |

3200 |

Installation dimension mm |

5410X1660X2500 |

5500X1800X3100 |

9000X2200X4000 |

9000X2700X5280 |

Gross weight kg |

850 |

1200 |

1500 |

3200 |

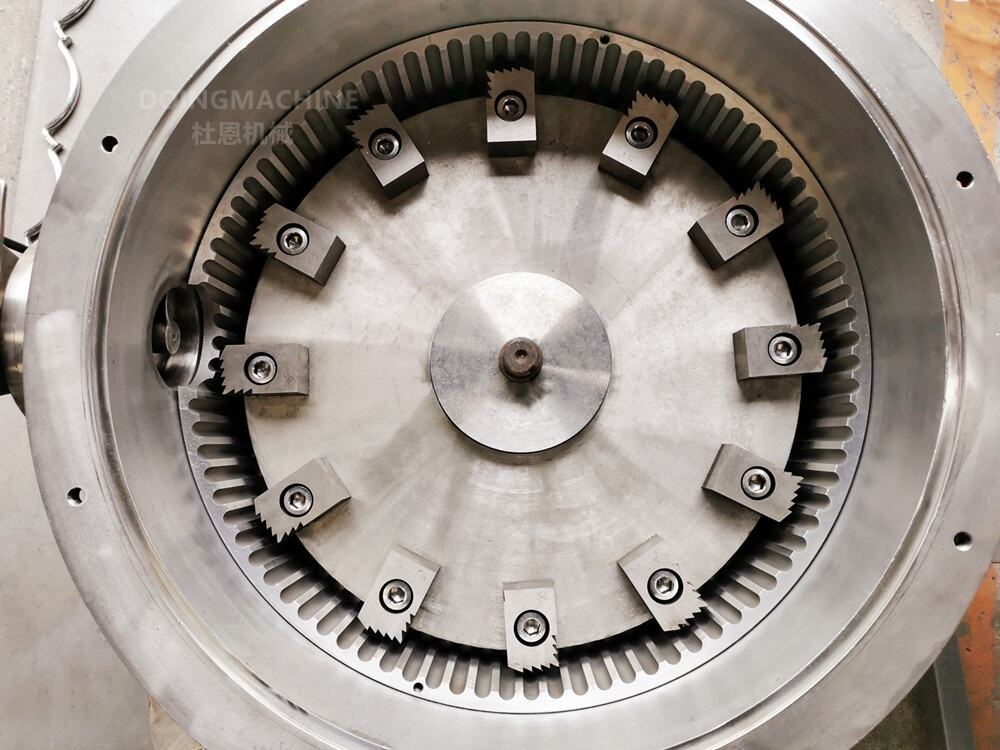

Grinding chamber inside

teeth liner can considerably increase life-span.

Grinding chamber outside

Screw feeder

DOINGMACHINE

The Micro air classifier powder grinding mill for chemical food from DOING MACHINE is an advanced and efficient device processing a wide number of chemical and food materials. The item is beautifully made with accuracy and revolutionary technology deliver excellent grinding performance and lower waste and dirt emissions.

The DOING MACHINE Micro air classifier powder grinding mill for chemical food is a taut and robust machine operates at high speeds, enabling it to grind many materials quickly and efficiently. The equipment is fitted having an effective engine enables it to keep a constant rate ensuring that the grinding process is constant and uniform. The mill can create up to several kilograms of powder each hour featuring its efficient design.

The Micro air classifier powder grinding mill for chemical food is well matched to processing materials are chemical as pigments, dyes, and resin powders. Additionally, it is ideal for grinding food products such as salt, sugar, and spices, thank you to its high-quality stainless-steel construction that insures the material is ground to a constant size texture. The mill operates in an entirely closed system, making sure there is no contamination from the product during the grinding procedure.

The DOING MACHINE Micro air classifier powder grinding mill for chemical food is incredibly simple and user-friendly to operate. The apparatus is equipped with an electronic control that enables users to set the grinding time and adjust the grinding speed, making the consumer has complete control of the grinding procedure. Furthermore, it is built with a safety interlock system this means that the product will perhaps not operate unless the hinged door securely closed.

The Micro air classifier powder grinding mill for chemical food from DOING MACHINE is extremely durable and requires minimal upkeep thanks to its high-quality construction and robust design. The unit is constructed with high-quality materials and elements, making sure it shall provide a long time of reliable service. Additionally, the product is created using user convenience in your mind, so routine maintenance are simple and uncomplicated to finish.

Copyright © Changzhou Doing Machine Co., Ltd All Rights Reserved | Blog | Privacy policy