Сушильна машина KJG Paddle є високопродуктивною, механічно змішувальною, непрямою системою нагріву для сушку, яка широко використовується для сушіння комунального шламу, промислового шламу, шламу з паперової промисловості, буронавальних глин, біомаси, переробленого навозу тощо.

Принцип роботи та застосування:

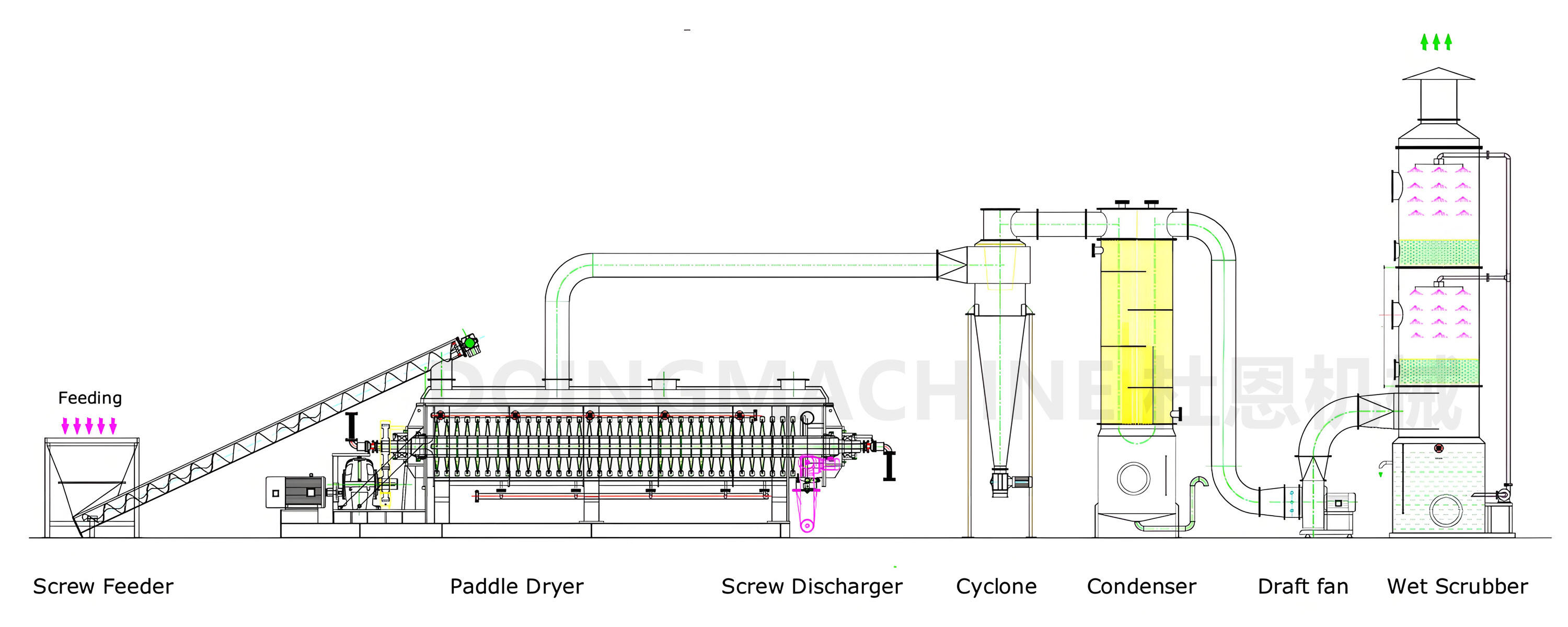

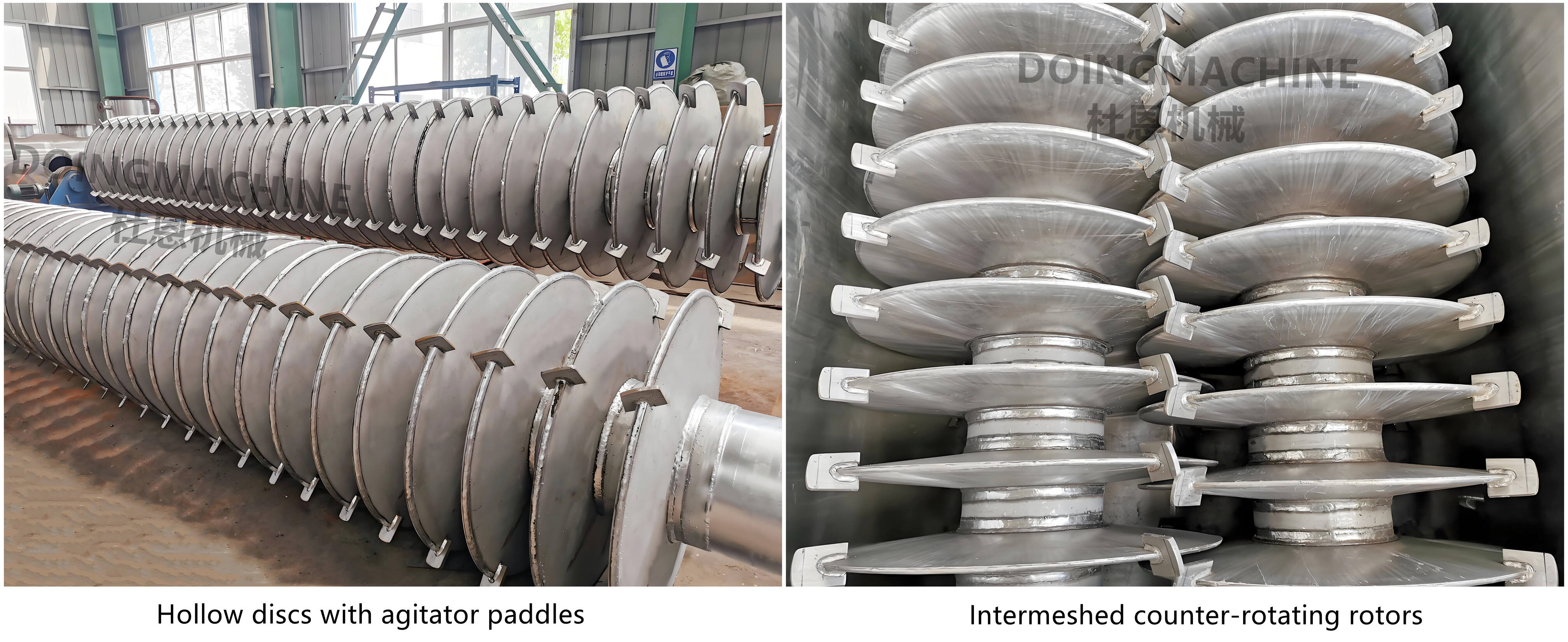

Принцип роботи: KJG Лопатковий Сушар є високопродуктивним, механічно перемішуваним, непрямим гріальним сушильним процесором. KJG лопатковий сушар складається з оболонкою трогу та двома протилежно оберталими валами з унікалими взаємопроникаючими порожніми дисками для створення інтенсивного перемішування та оптимізації передачі тепла. Гріюча середова, така як пар, гаряча вода або термальна олія, циркулює всередині гріючої оболонки та порожніх дисків для формування поверхні гріяння.

Мокрий матеріал пересувається через лопатковий сушар за допомогою мішальних лопат, зварених на периферії дисків. З регулярним мішанням, стриганням, переміщенням і передачею тепла, волога швидко і рівномірно еволює. Коли мокрий матеріал досягає протилежного кінця сушара, він виштовхнутий у випареному вигляді. Випарена волога висасується вентилятором і проходить через циклон, конденсатор і мокре очиснювач для значного зменшення забруднення повітря.

Застосування: Лопатковий сушар KJG зазвичай використовується для сушіння комунальних шламів, промислових шламів, паперового шламу, буровельних глин, біомаси, перевареної навозної маси тощо з продуктивністю процесу від 100 кг/год до 3 тонни/год.

Технічні характеристики:

1. Переваги порожнього диска: Порожній диск складається з двох напівдисків, зварених на краях. Він має такі переваги у порівнянні з традиційною клиновидною лопатою:

2. Висока теплове ефективність: Процес сушіння відбувається в добре теплоізольованому траншеї, а непряме гріяння може мінімізувати поток викидних газів, значно зменшуючи втрати тепла. Теплове ефективність може досягати 95%.

3. Екологічний дизайн: Система очищення викидних газів, яка включає циклон, трубчастий конденсатор, одноступеневу або двоступеневу мокру скрубберну установку, може досягти дуже високих стандартів емісій.

4. Компактна структура: Велика площа теплопередачі щодо об'єму досягається за допомогою порожніх дисків та ємності з оболонкою, через які протікає нагрівальний середовище. Як результат, отримується компактна машина з меншими вимогами до простору та нижчими витратами на монтаж.

5. Широке застосування: Сушильна установка KJG може обробляти різні види сировини, незалежно від того, чи є сировина густою рідиною, пастою, липким масивом або фільтр-кейком, мокрим порошком, маленькими гранулами тощо. Процес сушіння може бути партійним або неперервним.

Технічні параметри:

| Модель | KJG-10 | KJG-20 | KJG-30 | KJG-60 | KJG-80 | KJG-100 |

| Загальна площа нагріву (М2) | 10 | 20 | 30 | 60 | 80 | 100 |

| Приводний двигун (КВ) | 5.5 | 7.5 | 11 | 30 | 37 | 45 |

| Максимальна температура сушіння | 250 ℃ | |||||

| Швидкість випарювання | 8-10 кг води/М2/год | |||||

| гріюча середова | Пар або гаряче термічне масло | |||||

| Робочий тиск | 0.6 МПа | |||||

Примітка: Наш сушильний апарат KJG доступний у багатьох розмірах та конфігураціях. Вище наведені моделі з типовим дизайном є лише ознакою.

Питання та відповіді:

Q: Яка інформація потрібна для отримання ціни?

A: Наш сушильний апарат KJG адаптується під конкретний мокрий матеріал, потужність сушіння та джерело тепла. Потужність сушіння варіюється від 100 кг до 3 тони/год. Потрібна наступна інформація для розрахунку детальної ціни:

1) Детальна інформація про шлам, який потрібно пасувати:

2) Вміст вологи до пасування; цільовий вміст вологи у спаханому продукті;

3) Потрібна потужність пасування в кг/год;

4) Термічний носій: пар або гаряче термічне масло

5) Тип живлення: 220В/380В/415В/440В, 50/60Гц, три фази

Q: Який у вас звичайний термін виконання замовлення?

A: Усі наші пасувачі виготовляються на замовлення. Звичайний термін виконання становить 50-60 днів після отримання передплати.

Q: Як доставляється сушарка?

A: Сушарка з лопатками для шламу - це досить велика промислова машина, її вага становить від 3 тон до 50 тон. Коли площа нагріву менше 60 М2, корпус сушарки можна перевезти у контейнері HQ об'ємом 40 футів; при площі 60-150 М2 необхідно використовувати контейнер OT об'ємом 40 футів; більше 150 М2, корпус сушарки потрібно розбирати для перевезення.

Q: Які послуги після продажу ви можете надати?

A: 1) Усі наші машини повністю тестируються перед відправленням. Детальна інструкція з експлуатації, яка містить фотографії, відео про установку та експлуатацію, планувальні малюнки, електричні схеми тощо, доставляється разом з машиною. Отже, кінцевий користувач може легко встановити та експлуатувати машину.

2) За запрошенням клієнта технічні спеціалісти можуть бути вислані до цеху кінцевого користувача для встановлення, налагодження та навчання.

3) Забезпечувати технічну консультацію протягом всього терміну експлуатації та вигідні умови для постачання запчастин.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | БлогЯ не знаю.Політика конфіденційності