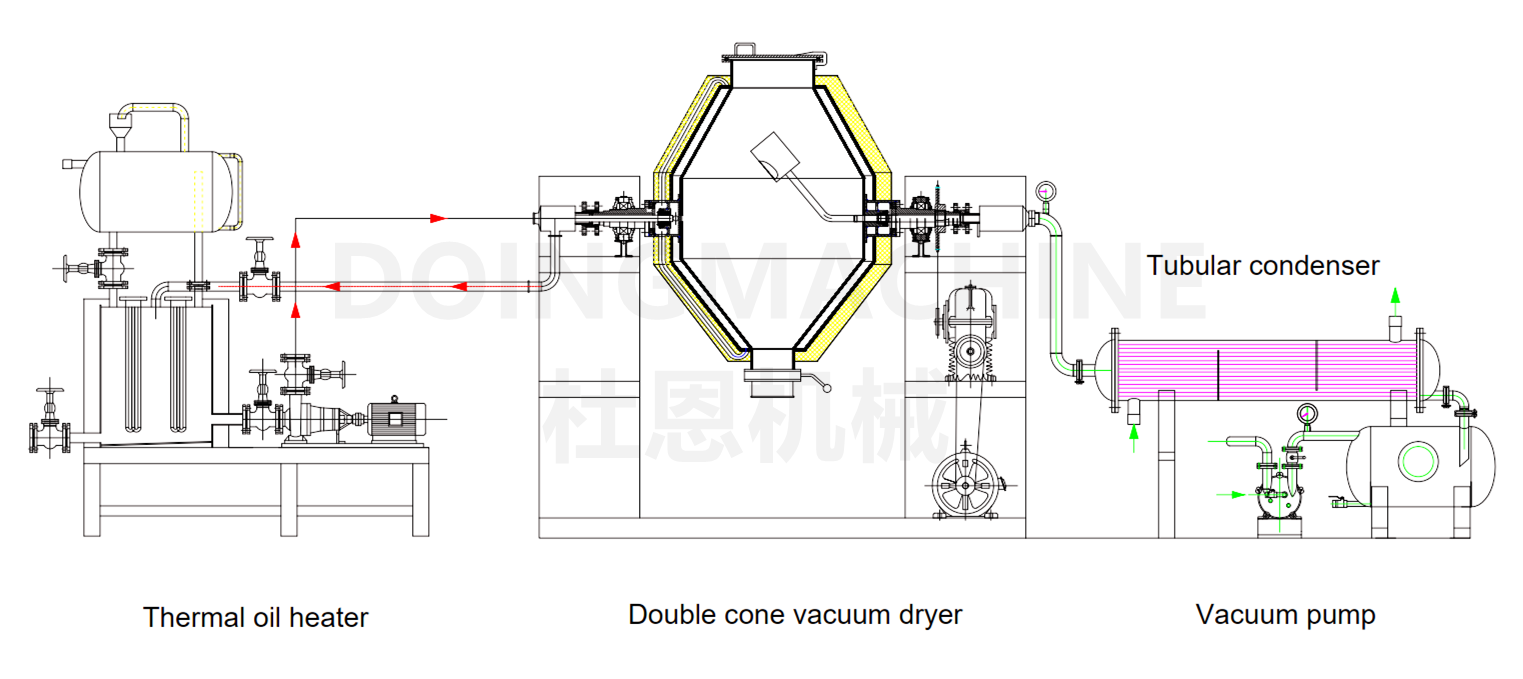

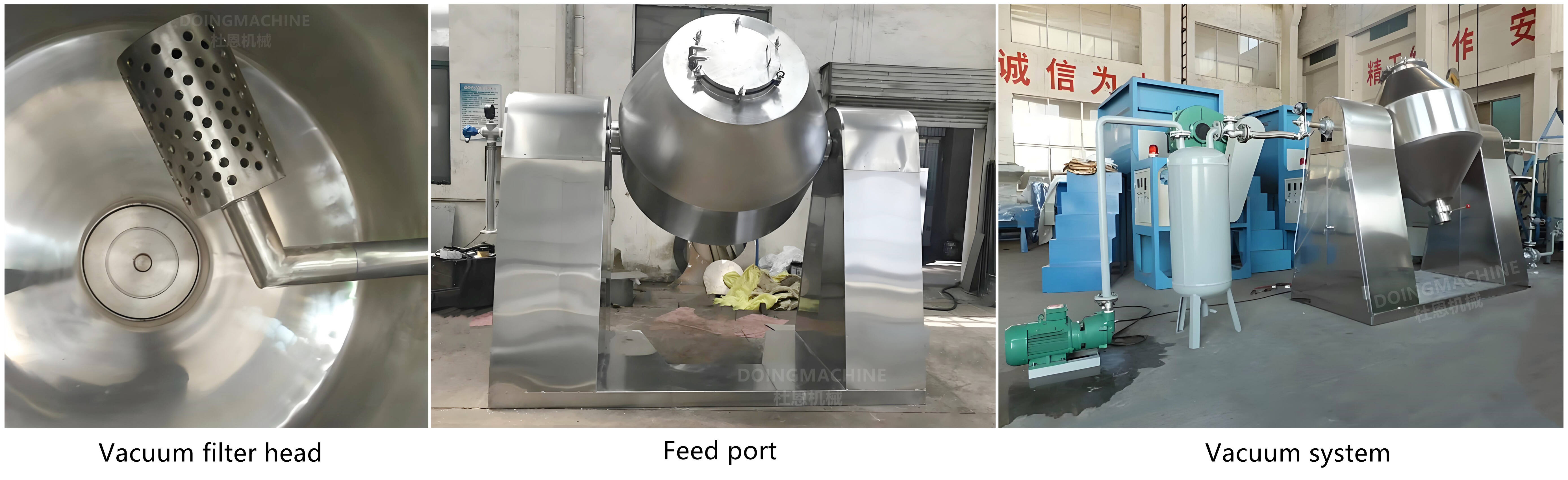

SZG Çift Koni Döner Boşluk Kurutma Cihazı, dolaylı ısıtma yöntemiyle kullanılan bir vakum döner kurutmadır. İki koni şeklindeki kurutma odası, ısıtmak için sıcak su, buhar veya termal yağ ile doldurulabilen ısıtma ceketi içerir.

İşlem sırasında, bi-konik kurutma odası düşük hızda döner ve ıslak malzemeyi sürekli olarak karıştırır ve ısıtılmış duvara temas eden malzemeyi yeniler. Top parçalayıcı kurutma odasına takılabilir ki bu da eşit bir şekilde kurutmak için topları parçalamaya yarar. Buharlaşan nem vakum pompa tarafından emilir. Eğer buharlaşan nem geri kazanılmak istiyorsa, tüplerden condansatör ve alıcı tank takılabilir.

SZG Çift Koni Rotasyonel Vakum Kurutucusu, gıda yiyecek, kimya ve ilaç sanayindeki ıslak toz ve granül ham maddeyi kurutmak için yaygın olarak kullanılır, özellikle sıcaklığa veya oksijene duyarlı ham madde için.

Teknik parametreler:

| Model | SZG-500 | SZG-1000 | SZG-2000 | SZG-3000 | SZG-5000 |

| Kurutma odası hacmi (L) | 500 | 1000 | 2000 | 3000 | 5000 |

| Yük kapasitesi (L) | 200 | 400 | 800 | 1200 | 2000 |

| Dönüş hızı (dev/dk) | 0-13 | 0-13 | 0-5 | 0-4 | 0-4 |

| motor gücü (KW) | 1.5 | 3 | 5.5 | 7.5 | 15 |

| Boşluk düzeyi (MPa) | -0.08-0.09 | ||||

| Cepheyapıbasıncı(Mpa) | ≤0,3 | ||||

| Yükseklik boyutu (mm) | 2350x800x2250 | 2860x1300x2800 | 3260x1400x2990 | 3760x1800x3490 | 4400x2500x4200 |

| Brüt ağırlık (kg) | 1200 | 2800 | 3600 | 6400 | 8600 |

Not: SZG Çift Koni Döner Vakum Kurutma Makinemiz, birçok boyutta ve yapılandırmada mevcuttur. Yukarıdaki modeller tipik tasarım ile yalnızca göstergeliktir.

SSS:

Q: Bir teklif almak için hangi bilgiler gereklidir?

A: Çift Koni Döner Vakum Kurutma Makinemiz, belirli ham madde, kurutma kapasitesi, ısı kaynağı vb. gibi faktörlere göre özelleştirilmiştir. Ayrıntılı bir teklif çıkarmak için aşağıdaki bilgiler gereklidir:

1) Ham madde adı, toplu yoğunluk ve parçacık boyutu vb. Deneme üretim veya kurutma testleri için örnekler gerekebilir.

2) Kurutmadan önceki nem oranı; kurutulmuş üründe hedeflenen nem oranı.

3) Kurutma kapasitesi/girdisi kg/saat cinsinden?

4) Kurutma için hangi ısı kaynağı kullanılacak? Buhar, sıcak su veya sıcak termal yağ.

5) Önerilen kurutma sıcaklığı

6) Enerji türü. 220V/380V/415V/440V, 50/60Hz, üç faz.

Soru: Normal teslimat süreniz nedir?

A: Tüm makinelerimiz özel olarak tasarlanmıştır. Normal teslimat süresi, ön ödeme alındıktan sonra 40-50 gündür.

Soru: Makine nasıl paketlenir?

A: Makina standart ahşap kutuda paketlenir;

S: Hangi türden sonra satış hizmeti sunabilirsiniz?

C: 1) Tüm makinelerimiz sevkiyat öncesi tamamen test edilir. Makine ile birlikte ayrıntılı işletim kılavuzu, fotoğraflar içeren, montaj ve işletim videoları, düzenlemeler, elektrik şemaları vb. teslim edilir. Böylece son kullanıcı makineyi kolayca kurabilir ve kullanabilir.

2) Müşterinin davetine yanıt olarak, teknisyenler son kullanıcının atölyesine montaj, komisyonlama ve eğitim için gönderilebilir.

3) Yaşam boyu teknik danmanı ve uygun yedek parçalar sağlar.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | blog|Gizlilik Politikası