Вакуумный реактор SZG специально разработан для процессов сушки, смешивания и конденсации гранулированных пластиков: чипсов, бусин, пластин, гранул, обрезков и т.д.

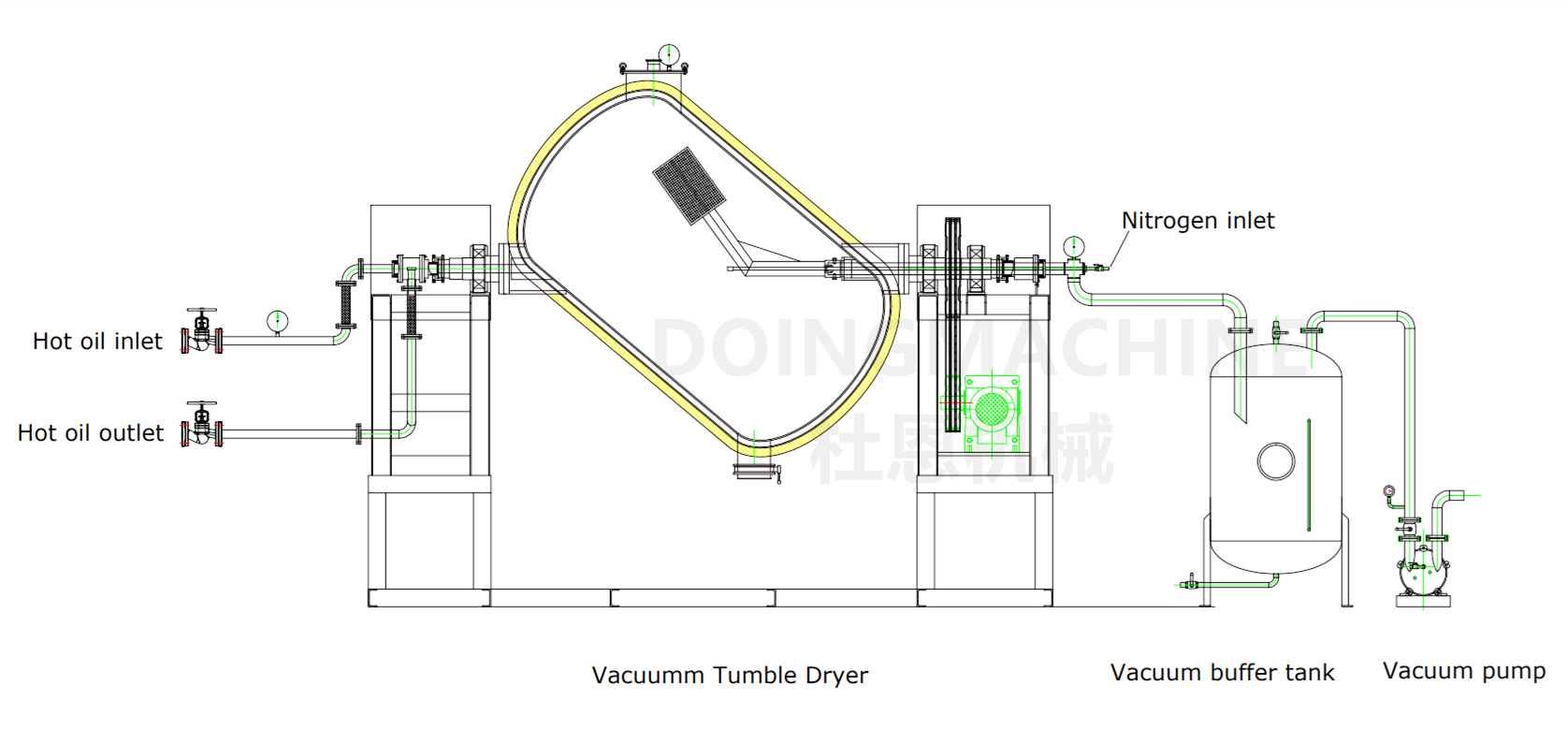

Вакуумный опрокидывающийся сушильный аппарат SZG (или вакуумный опрокидывающийся реактор) является непрямым вакуумным опрокидывающимся сушильным аппаратом. Цилиндрическая камера сушки имеет нагревательный кожух, который можно заполнить паром или тепловым маслом для нагрева. Внутри камеры сушки приварены мешалки для усиления эффекта перемешивания.

Во время работы цилиндрическая сушильная камера вращается на низкой скорости, чтобы постоянно смешивать и обновлять влажный материал, соприкасающийся с нагретой стенкой. В сушильную камеру может быть подан азот для предотвращения окисления сырья. Испаренная влага отсасывается вакуумным насосом. Если испаренная влага должна быть восстановлена, можно установить трубчатый конденсатор и приемный бак.

SZG Вакуумный опрокидывающийся сушилка специально разработана для процессов сушки, перемешивания и конденсации гранулированных пластиков: чипсов, бусин, пластин, гранул, обрезков и т.д.

1) Композиции PET и PBT

2) Твердофазное постконденсирование PA 6, PA 6.6, PES, PET, PBT, PTT

3) Сушка или предварительная кристаллизация пластиковых чипсов или гранул

Технические параметры:

| Модель | SZG-2000 | SZG-3000 | SZG-5000 | SZG-8000 | SZG-10000 |

| Объем камеры сушки (Л) | 2000 | 3000 | 5000 | 8000 | 10000 |

| Грузоподъёмность (Л) | 1000 | 3000 | 5000 | 8000 | 10000 |

| Скорость вращения (об/мин) | 0-13 | 0-13 | 0-5 | 0-4 | 0-4 |

| Приводной двигатель (КВт) | 5.5 | 7.5 | 15 | 22 | 30 |

| Степень вакуума (MPa) | -0.08-0.09 | ||||

| Рабочее давление в оболочке (Мпа) | ≤ 0,3 | ||||

| Рабочая температура (℃) | ≤280 | ||||

| Размер установки (мм) | 3260x1400x2990 | 3760x1800x3490 | 4400x2500x4200 | 5500x2800x4500 | 6250x2900x4950 |

| Вес с упаковкой (кг) | 3600 | 6400 | 8600 | 10000 | 12000 |

Примечание: Наш вакуумный опрокидывающий сушильщик SSP / Реактор доступен во многих размерах и конфигурациях. Приведенные выше модели с типовым дизайном носят исключительно ознакомительный характер.

Часто задаваемые вопросы:

В: Какую информацию нужно предоставить, чтобы получить коммерческое предложение?

Ответ: Наш вакуумный опрокидывающий сушильщик SSP настраивается в зависимости от конкретного сырья, емкости сушки, температуры нагрева и т.д. Следующая информация необходима для составления подробной котировки:

1) Название сырья, его насыпная плотность и размер частиц и т.д. Возможно потребуется образец для пробного производства или тестирования сушки.

2) Если для сушки: содержание влаги до сушки; целевое содержание влаги в высушенном продукте.

3) Производительность сушки/ввод в кг/партию?

4) Температура нагрева?

5) Тип электропитания. 220В/380В/415В/440В, 50/60Гц, трехфазный.

В: Каков ваш обычный срок поставки?

О: Все наши машины создаются под заказ. Обычный срок поставки составляет 40-50 дней после получения авансового платежа.

В: Как упакована машина?

О: Машина упакована в стандартный фанерный ящик;

В: Какие послепродажные услуги вы можете предоставить?

О: 1) Все наши машины полностью тестируются перед отправкой. Подробная операционная инструкция, которая включает фотографии, видео установки и эксплуатации, чертежи размещения, электрические схемы и т.д., поставляется вместе с машиной. Таким образом, конечный пользователь может легко установить и эксплуатировать машину.

2) По приглашению клиента техники могут быть направлены в мастерскую конечного пользователя для установки, пуско-наладочных работ и обучения.

3) Предоставление пожизненной технической консультации и выгодных запчастей.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Блог| Политика конфиденциальности