Providing the PZG collection reduced temperature level rotating vacuum cleaner paddle clothes dryer for sludge, an ideal service towards completely dry out your sludge efficiently!

Our PZG reveal clothes dryer operates along with reduced problems which significantly reduces energy use avoids temperature level issues for your product. The device is made from high-quality steel, guaranteeing resilience broadening the period of your clothes dryer, making it an response cost-effective.

The cleanser rotating innovation connected helped due to the clothes dryer enhances the drying out efficiency, allowing finish drying out of sludge. Additionally, the paddles coming from the clothes dryer ensure products relocate uniformly with the device, avoiding build-up or even caking.

The cleanser work around the PZG collection not simply increases the drying out treatment however furthermore assurances the technique happens within an oxygen-free atmosphere, avoiding burning providing an effective treatment drying out. The cleanser work furthermore reduces the possibilities of fouling truly assists towards take care of the high top premium of solutions items.

Our clothes dryer has higher efficiency thermal significance it might recuperate the latent temperature level used in the method drying out. The appearance thermal of clothes dryer is to ensure that the home heating uniformity is excellent, guaranteeing constant drying out of this particular sludge. Perhaps you're ensured of determination in your services or products each time you use our reveal PZG temperature level is reduced cleanser paddle clothes dryer for sludge.

Safety and safety is our issue, therefore our team produced the clothes dryer in a style that fulfills market safety demands. Our clothes dryer posses an safety alarm system that differentiates condition operating breakdowns, that makes it a service risk-free your demands.

The PZG collection reduced temperature level rotating vacuum cleaner paddle clothes dryer for sludge will available differing abilities, allowing you towards select the one that finest suits your production demands. The simpleness of maintenance treatment creates the clothes dryer perfect for each professionals those who're a brand-new comer towards the market. Our product is effective, efficient, simple towards deal with.

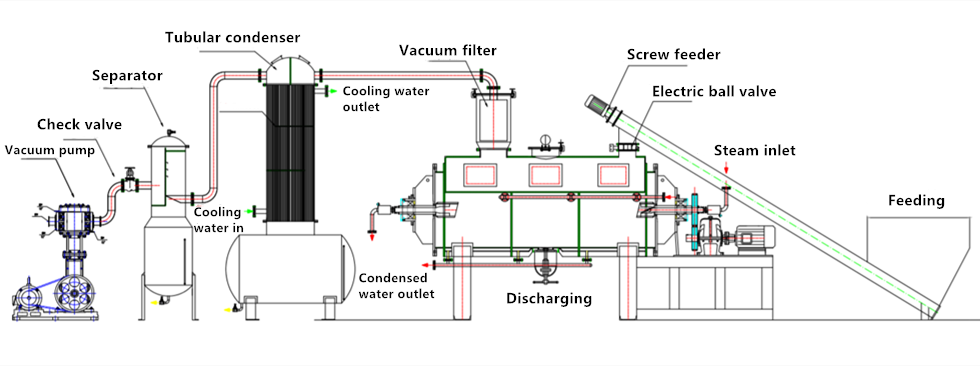

1. Used for drying or reacting of pastes, filter cakes, powders, and granules under vacuum condition;

2. Heating area: 10-300 M2

3. Volume of drying chamber: 500-25000 L

4. Working type: Batch type or continuous

5. Heat source: steam, hot water or hot oil

1) High thermal efficiency which can reach 95%

2) Heat transfer medium does not contact the product.

3) Gas is not used to convey the product. Off-gas flow is minimal.

4) Precise control of temperature

5) Uniform product quality, through mixing and movement of the product

6) High heat transfer area to process volume ratio - reduced floor space

7) Easy to operate, requires minimal attention

8) Safer than direct drying when processing combustible material

9) Simple durable design for easy and low maintenance

Main technical parameters

Model |

PZG-600 |

PZG-1000 |

PZG-2000 |

PZG-4000 |

PZG-6000 |

PZG-8000 |

Volume L |

600 |

1000 |

2000 |

4000 |

6000 |

8000 |

Working volume L |

420 |

700 |

1400 |

2800 |

4200 |

5600 |

Heat transfer area M2 |

6 |

10 |

20 |

40 |

60 |

80 |

Evaporation rate kg/M2/hr |

6-10 |

6-10 |

6-10 |

6-10 |

6-10 |

6-10 |

Working temp. oC |

60-280 |

60-280 |

60-280 |

60-280 |

60-280 |

60-280 |

Vacuum degree Pa |

300-1500 |

300-1500 |

300-1500 |

300-1500 |

300-1500 |

300-1500 |

PZG-6500 vacuum paddle dryer in Hungary

PZG-3000 vacuum paddle dryer in India

PZG-2000 vacuum paddle dryer in China

PZG-8000 vacuum paddle dryer in China

PZG-3000 vacuum paddle dryer in China

PZG-6000 vacuum paddle dryer in Canada

Copyright © Changzhou Doing Machine Co., Ltd All Rights Reserved | Blog | Privacy policy