ZKS Vakuum-Förderband (oder pneumatisches Förderband) ist das zuverlässigste und wirtschaftlichste Fördergerät zur Bewegung freifließender Pulver, Granulate, Pellets und anderer trockener Massengutmaterialien durch pneumatische Saugwirkung.

Das ZKS-Vakuumbelüftungsgerät (oder pneumatische Belüftung) ist das zuverlässigste und wirtschaftlichste Fördergerät zum Transportieren freifließender Pulver, Granulate, Pellets und anderer trockener Massengutmaterialien durch pneumatische Saugkraft. Das Vakuumbeförderungssystem besteht aus einer Aufnahmestation, Schläuchen, einem Vakuumbeförderer mit Filter, einem Sekundärfilter und einer Luftpumpe.

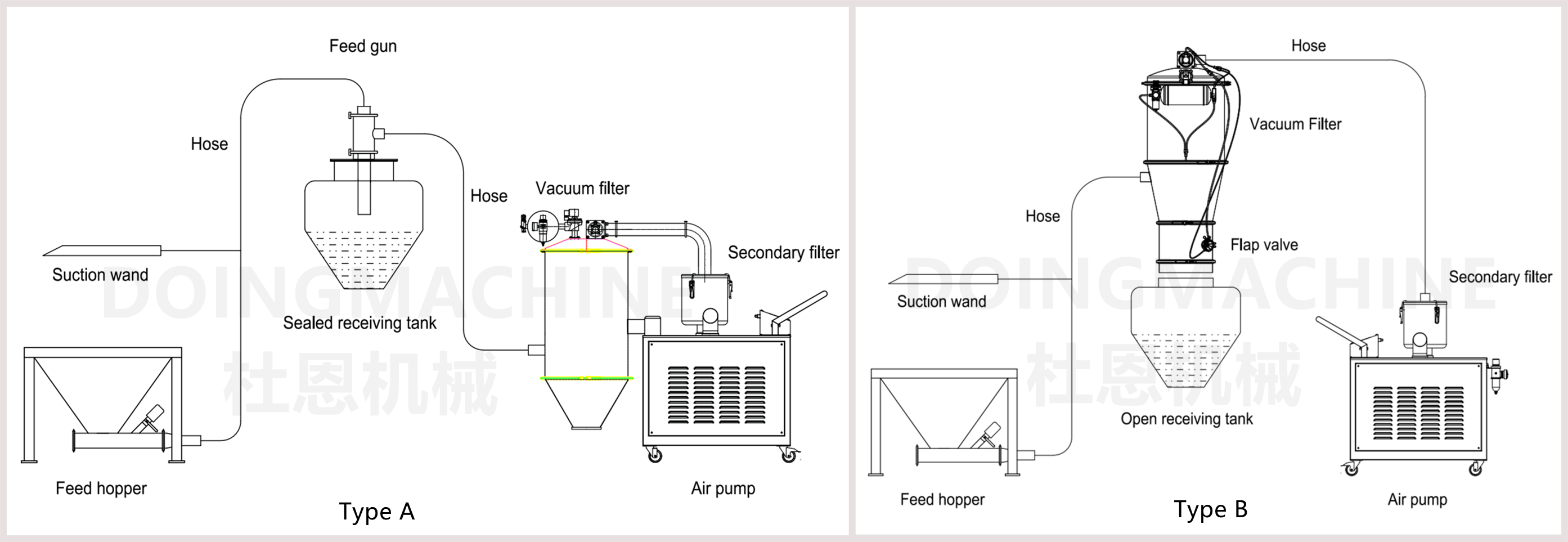

Die Luftpumpe erzeugt einen starken Luftstrom, der die Massengutmaterialien von der Aufnahmestation zum Empfangstank transportiert. Es gibt zwei Arten von Vakuumbelüftungen:

Typ A: Füttern in einen verschlossenen Tank/Hopper. Stecken Sie die Füllpistole in den luftdichten Empfangstank, wo sich Feststoffe und Luft aufgrund unterschiedlicher Dichte trennen. Diese Konstruktion wird oft verwendet, um Pulvermischer oder Speicherbehälter zu füllen.

Typ B: Füttern in einen offenen Tank/Hopper. Montieren Sie den Vakuumbeförderer über dem offenen Empfangstank. Das feststoffliche Material wird durch röhrenförmige Filter getrennt und dann über eine pneumatische Klappe abgeleitet.

Technische Parameter:

| Modell | ZKS-3 | ZKS-4 | ZKS-5 | ZKS-7 | ZKS-11 |

| Förderkapazität (kg/h) | 1200 | 2000 | 3000 | 4000 | 6000 |

| Luftpumpe (KW) | 3 | 4 | 5.5 | 7.5 | 11 |

Hinweis: Die Förderkapazität hängt von der Schüttgütedichte und dem Partikelgröße des Rohstoffs, der Förderhöhe und dem horizontalen Abstand ab. Die in der obigen Tabelle angegebene Fördermenge wurde mit Weizenmehl und einer 4 Meter langen Förderröhre gemessen.

FAQ:

F: Welche Informationen werden benötigt, um ein Angebot zu erhalten?

A: Unser Vakuumbelüftungsfoerderer ist maßgeschneidert. Folgende Informationen sind erforderlich, um ein detailliertes Angebot auszuarbeiten:

1) Welche Rohstoffe Sie transportieren/massen werden. Ein Rohstoffprobe könnte für Versuchsproduktion oder Tests benötigt werden;

2) Schüttgütedichte und Partikelgröße des Rohstoffs;

3) Förderhöhe und -distanz;

4) Förderleistung in kg/h;

4) Art der Spannungsversorgung: 220V/380V/415V/440V, 50/60Hz, Ein-/Dreiphasig

F: Was ist Ihre normale Lieferzeit?

A: Alle unsere Maschinen werden nach Maß hergestellt. Die normale Lieferzeit beträgt 30-40 Tage nach Eingang der Anzahlung.

F: Wie wird die Maschine verpackt?

A: Die Maschine wird in einer Standard-Sperrholzbox verpackt;

F: Welche Art von Nachverkaufs-Service können Sie bieten?

A: 1) Alle unsere Maschinen werden vor dem Versand vollständig getestet. Ein detailliertes Bedienungshandbuch, das Fotos, Installations- und Betriebsvideos, Layoutzeichnungen, elektrische Zeichnungen usw. enthält, wird mit der Maschine geliefert. Somit kann der Endbenutzer die Maschine leicht installieren und bedienen.

2) Aufgrund der Anforderungen des Kunden können Techniker in die Werkstatt des Endbenutzers geschickt werden, um Installation, Inbetriebnahme und Schulung durchzuführen.

3) Leistungsstarke technische Beratung und günstige Ersatzteile für den gesamten Lebenszyklus.

Copyright © Changzhou Doing Machine Co., Ltd. All Rights Reserved | Blog|Datenschutzrichtlinie